Educated engineers, handy installers, and crafty convertors all know what cellular rubber is and what makes it an exceptional energy efficient insulator, cushiony protector, sealing gasket, and more... but do you? Cellular rubber, sometimes call sponge rubber, is a lightweight, compressible type of foam rubber that has an either open or closed-cell structure. This is in contrast to normal rubber, which has no cell structure. Regardless of the chemical mix (EPDM, NBR, or CR for example) or application, cellular foam is manufactured in accordance with expansion processes and is used in a variety of industries and markets. Now that you have the basics, let’s dive into some specifics about cellular rubber. We have complied a list of common questions from our customers to provide a simple guide.

1. What is the difference between open-cell and closed-cell rubber?

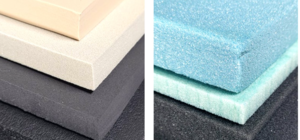

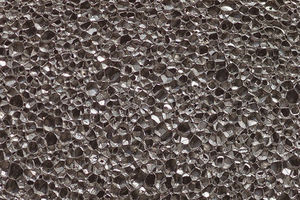

There are two main varieties of cellular rubber. The first is open-cell rubber in which the distinctive cells are open and interconnected to the neighboring cells. This pattern allows air and moisture to seep in easily giving this rubber its absorbent quality and the ability to regain its physical form after compression. This is important in construction applications and the FillPro Open Cell backer rod is an example. The second is closed-cell like ArmaFlex elastomeric insulation, that is made up of cells that do not connect, but are completely closed off from each other. This type will not allow moisture ingress or wick moisture because water cannot pass from cell to cell, making it suitable for applications with a high presence of moisture or condensation. Closed-cell rubber does not require an outer skin or jacketing when installed and most sealants, caulk or other chinking materials will also stick more easily to closed cell rubber due to the bonding surface area being better comparatively to an open-cell product.

There are two main varieties of cellular rubber. The first is open-cell rubber in which the distinctive cells are open and interconnected to the neighboring cells. This pattern allows air and moisture to seep in easily giving this rubber its absorbent quality and the ability to regain its physical form after compression. This is important in construction applications and the FillPro Open Cell backer rod is an example. The second is closed-cell like ArmaFlex elastomeric insulation, that is made up of cells that do not connect, but are completely closed off from each other. This type will not allow moisture ingress or wick moisture because water cannot pass from cell to cell, making it suitable for applications with a high presence of moisture or condensation. Closed-cell rubber does not require an outer skin or jacketing when installed and most sealants, caulk or other chinking materials will also stick more easily to closed cell rubber due to the bonding surface area being better comparatively to an open-cell product.

2. Why should you use cellular rubber over solid rubber?

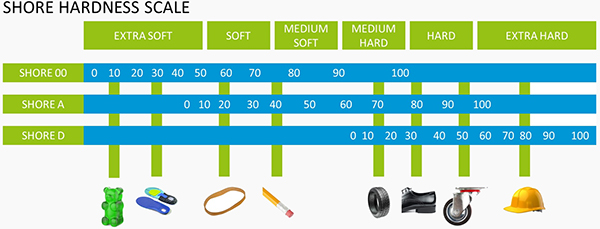

At the most basic level, the difference between cellular rubber vs. solid rubber is about air. Both types of materials provide sealing and insulation properties, but cellular rubber provides better cushioning while solid rubber can provide stronger impact resistance. Solid rubber is created in the conventional way through the process of vulcanization. However cellular rubber is different because it has a defined cellular structure. It is created using gas developing agents which introduce air, thus making the material less hard and dense but more heat resistant and absorbent. Cellular rubber, in comparison to solid rubber has lesser density and thus less cost implications as material (mass) per unit volume reduces. Another main benefit of cellular rubber is its softness rating on the Shore A scale—cellular foams are usually even softer than solid rubber. These soft rubber materials can be used to seal anything from car doors to packing to aircraft components.

At the most basic level, the difference between cellular rubber vs. solid rubber is about air. Both types of materials provide sealing and insulation properties, but cellular rubber provides better cushioning while solid rubber can provide stronger impact resistance. Solid rubber is created in the conventional way through the process of vulcanization. However cellular rubber is different because it has a defined cellular structure. It is created using gas developing agents which introduce air, thus making the material less hard and dense but more heat resistant and absorbent. Cellular rubber, in comparison to solid rubber has lesser density and thus less cost implications as material (mass) per unit volume reduces. Another main benefit of cellular rubber is its softness rating on the Shore A scale—cellular foams are usually even softer than solid rubber. These soft rubber materials can be used to seal anything from car doors to packing to aircraft components.

3. What does cellular rubber compression set and compression deflection mean?

Compression set is defined as the property of rubber that allows it to return its original thickness after being exposed to compressive forces. Thanks to the pockets or cells in cellular rubber, it has excellent compression set. Compression deflection on the other hand is the force required to compress a unit volume of rubber. Solid rubber has no pockets whatsoever and a high value of compression deflection.

4. What is tensile strength and elongation?

Tensile strength is how much force or stress a rubber material can withstand before breaking or failing. Abrasion, tear and impact resistance are all affected by tensile strength. Elongation is the percentage of increase in length (or stretching) of a rubber material with respect to its original dimensions as a result of tensile force being applied to the sample itself. Elongation is inversely proportional to hardness, tensile strength, and modulus. Right when elongation stops, breakdown of the cellular structure begins.

5. What are some of the best applications for cellular rubber?

Cellular rubber is a modern miracle and each type of elastomer has its advantages and niche. Some cellular rubber materials are best being used to insulate low temperature systems, while others thrive on higher temperature applications. Some have a great ability to absorb shock, others flotation capacity and fluid immersion. Further, many cellular rubber products can be converted into thousands of products from protective padding, packaging materials, gaskets, seals, and more. The great benefit of Armacell’s cellular rubber is that we have a solution for any application or need. From building materials, HVAC, construction, or plumbing to aerospace, automotive, medical, and athletics, Armacell has a foam for that.

Cellular rubber is a modern miracle and each type of elastomer has its advantages and niche. Some cellular rubber materials are best being used to insulate low temperature systems, while others thrive on higher temperature applications. Some have a great ability to absorb shock, others flotation capacity and fluid immersion. Further, many cellular rubber products can be converted into thousands of products from protective padding, packaging materials, gaskets, seals, and more. The great benefit of Armacell’s cellular rubber is that we have a solution for any application or need. From building materials, HVAC, construction, or plumbing to aerospace, automotive, medical, and athletics, Armacell has a foam for that.

Do you have other questions about cellular rubber or need help choosing the right material? Our sales and technical teams are always happy to help. To get started, contact us here.