Why Insulate Ducts?

High-performance schools, hospitals and commercial spaces of all kinds need high-performing duct insulation. Air ducts are at the heart of a building’s efficiency, productivity and indoor air quality.

High-performance schools, hospitals and commercial spaces of all kinds need high-performing duct insulation. Air ducts are at the heart of a building’s efficiency, productivity and indoor air quality.

Properly insulated ducts help reduce energy waste, resist the spread of mold and fibers, and reduce noise for a more effective learning environment.

Yet more than 70 percent of ducts in America’s buildings are uninsulated. In other cases, schools, healthcare facilities and other buildings spend millions of dollars cleaning and replacing fiberglass ductwork that has been damaged by moisture and mold.

Closed-cell, fiber-free elastomeric foam duct liner provides proven, safe and durable protection – with the added benefit of noise reduction that external wraps don't have.

FACT: Only AP ArmaFlex, AP Coilflex and AP Spiralflex insulation are uniquely engineered and patented for better duct systems without fibers.

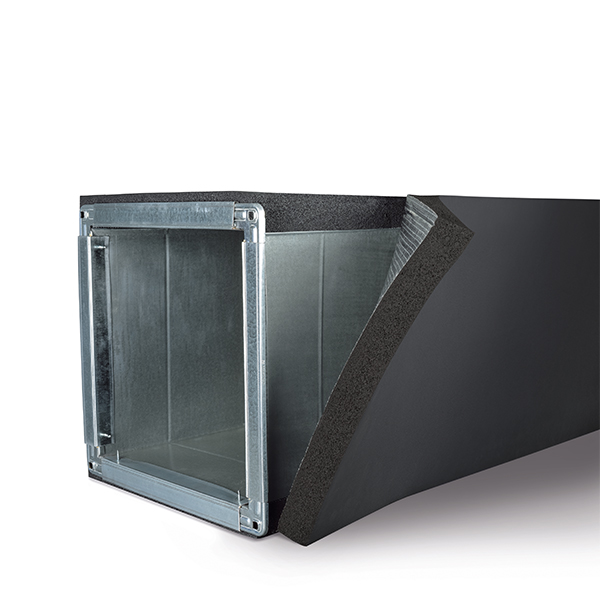

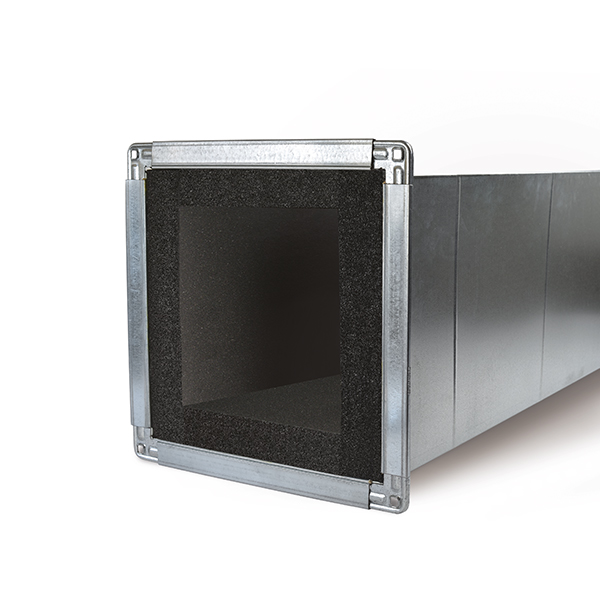

Duct Lining vs. Wrap

Lining a duct with elastomeric foam like AP ArmaFlex, AP CoilFlex and AP SpiralFlex not only offers thermal protection from energy loss and condensation control, but it also brings superior sound absorption and vibration dampening from airborne and structure-borne HVAC noise. Another advantage is that duct fabricators may be able to pre-line ducts on automatic coil lines in the shop, saving installation time in the field.

Wrapping a duct may be the best option when access to the inside of the duct is impossible, perhaps during a retrofit of an existing mechanical system or renovation of an older building. Wrapping the duct with AP ArmaFlex still provides excellent protection from energy loss and condensation, as well as some vibration-dampening benefits.

Long-Term Efficiency and Cost-Saving Solution

R-4.2 performance at 1" thickness R-6 at 1-1/2", R-8 at 2"

Meets requirements of ASHRAE 90.1

Durable non-fibrous structure is long-lasting and requires fewer replacements over time

Smooth surface reduces the need for maintenance and cleaning

Moisture Protection

Fiberglass lining, when damaged, allows moisture penetration and "wicking" that lead to mold, loss of thermal efficiency and costly replacement

Unlike fiberglass, a closed-cell foam structure acts as a built-in vapor retarder (jacket)

Built-In Mold Resistance

Only Armacell duct liners are made with EPA-registered Microban® antimicrobial additive that can’t wear off or wash away

Fiber-Free IAQ Protection

Elastomeric foam does not contribute to fibers in the indoor air circulation

Formaldehyde-free and low VOC

First insulation products tested and GREENGUARD Gold certified for low chemical emissions into indoor air

Clean, dust-free, non-particulating, non-eroding

Safe for Schools, Healthcare Facilities, Government and Military Institutions and Any Commercial Buildings

Plenum-rated for fire and smoke

Meets the critical 25/50 flame spread and smoke generation requirements of National Fire Protection Agency standards 90A and 90B for duct linings

Excellent Noise Protection

Reduces HVAC noise levels through sound absorption and blocking

Good NRC value (up to 0.60), excellent STC (Class 25)

Dense enough to provide excellent sound deadening (vibration damping) of HVAC rattle in metal ducts

Lower Initial Costs

No expensive encapsulating film required

No costly secondary inner metal wall required

It’s time to insulate air ducts correctly with the IAQ Insulation™ from Armacell.