Gaskets can be defined as key components of industrial applications used to help seal joints, limit vibration, and prevent leaks. Gaskets used in the aerospace industry fill the spaces between surfaces on aircraft, spaceships, and commercial vessels. They also help provide barriers against flame or fire, provide vibration damping, and support cushioning. Aircraft gaskets are utilized in various applications including:

Gaskets can be defined as key components of industrial applications used to help seal joints, limit vibration, and prevent leaks. Gaskets used in the aerospace industry fill the spaces between surfaces on aircraft, spaceships, and commercial vessels. They also help provide barriers against flame or fire, provide vibration damping, and support cushioning. Aircraft gaskets are utilized in various applications including:

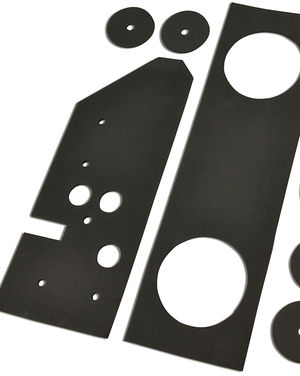

- Gaskets or seals between mating surfaces (Cabin, windows, lavatories, doors)

- Sound damping, vibration, and noise control

- Pads or cushioning

- Rubber stripping

Of all foam material product characteristics, the most important for the aerospace industry is the flammability requirement. Armacell performs flame testing to ensure select elastomeric component foam products that are specified have been tested to industry standards to meet many stringent aerospace requirements. Several of our products meet the flammability requirements of the Federal Aviation Administration (FAA) regulations at specific thicknesses. Some of our ArmaCompTM products including ArmaSport, EnsoLite, and Monarch component foam products have been tested to and pass the stringent horizontal and 12 second vertical burn requirements of FAR 25.853 at specific thicknesses. Additionally, several of our cellular materials are also UL94 V-0 vertical burn rated at specific thicknesses.

Of all foam material product characteristics, the most important for the aerospace industry is the flammability requirement. Armacell performs flame testing to ensure select elastomeric component foam products that are specified have been tested to industry standards to meet many stringent aerospace requirements. Several of our products meet the flammability requirements of the Federal Aviation Administration (FAA) regulations at specific thicknesses. Some of our ArmaCompTM products including ArmaSport, EnsoLite, and Monarch component foam products have been tested to and pass the stringent horizontal and 12 second vertical burn requirements of FAR 25.853 at specific thicknesses. Additionally, several of our cellular materials are also UL94 V-0 vertical burn rated at specific thicknesses.

Another benefit of using our component foams in the aerospace industry is to help control noise or vibration. Material Specification Engineers seek out damping products that can help alleviate noise due to movement. Vibration damping cellular materials can be installed under aircraft interior floor panels, seat tracks, windows, galleys, lavatories, storage bins, and other areas where vibration and rattling can occur over the course of a plane’s lifecycle.

ArmaSport and EnsoLite products are offered in a variety of densities and compression deflection (firmness) ranges. Monarch products also offers a variety of densities made of tight, closed-cell PVC/NBR based foam products. These products offer a broad range of soft, flexible, closed-cell PVC/NBR and PVC/NBR/CR based foam products for sealing and gasket applications.

The Best Type of Foam for Gaskets

Closed-cell foams have an advantage over open or semi-closed cell foams due to a better resistance to water absorption. If an application needs strength and moisture resistance, then a closed-cell foam is better suited. With over 70 years of expertise, Armacell has the expertise to create innovative foam solutions for converters and fabricators that supply gasketing and sealing products to aerospace OEMs. Armacell is continuously working to innovate our varied cellular products and formulations so we may meet the changing needs of the aerospace industry and its suppliers. Our technical team is well-versed in the requirements and application of foams, so please contact us for any questions or to find products that meet your needs.