Despite being post-pandemic, it is important for us to understand how viruses, bacteria, mold, and other contaminants can impact our air quality. Doubly important is how building owners can help protect occupants inside of buildings where clean air quality is a vital concern. Thankfully, some construction materials and many products now include antibacterial or antimicrobial protection. But how do we know which is best? And are they the same thing?

Despite being post-pandemic, it is important for us to understand how viruses, bacteria, mold, and other contaminants can impact our air quality. Doubly important is how building owners can help protect occupants inside of buildings where clean air quality is a vital concern. Thankfully, some construction materials and many products now include antibacterial or antimicrobial protection. But how do we know which is best? And are they the same thing?

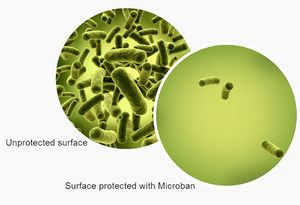

Both antibacterial and antimicrobial products help protect us from pathogens and sickness. The primary difference between antibacterial and antimicrobial substances however is the types of microorganisms they act upon. Antibacterial technologies are effective against a broad spectrum of harmful bacteria, and they will typically incorporate several active ingredients, allowing for successful application. While antibacterial cleansers destroy bacteria, antimicrobial has the advantage. An antimicrobial product is effective against a wide spectrum of microbes: this includes bacteria, mold, fungi and even viruses. Antimicrobial technologies go even further by offering a greater level of product protection as they continuously inhibit the growth of microbes on surfaces for very long periods of time. The broad spectrum performance of antimicrobial substances makes them perfect for use in hygiene critical environments such as schools, hospitals, and commercial facilities.

Both antibacterial and antimicrobial products help protect us from pathogens and sickness. The primary difference between antibacterial and antimicrobial substances however is the types of microorganisms they act upon. Antibacterial technologies are effective against a broad spectrum of harmful bacteria, and they will typically incorporate several active ingredients, allowing for successful application. While antibacterial cleansers destroy bacteria, antimicrobial has the advantage. An antimicrobial product is effective against a wide spectrum of microbes: this includes bacteria, mold, fungi and even viruses. Antimicrobial technologies go even further by offering a greater level of product protection as they continuously inhibit the growth of microbes on surfaces for very long periods of time. The broad spectrum performance of antimicrobial substances makes them perfect for use in hygiene critical environments such as schools, hospitals, and commercial facilities.

Armacell’s Antimicrobial Protection

Since 2006, Armacell has manufactured foam insulation products made with Microban® antimicrobial product protection – and we were the first foam insulation provider to do so. Microban utilizes built-in antimicrobial technologies to safeguard and help keep products cleaner, fresher, and protected for longer periods of time. Using antimicrobials such as this allows consumers to protect products from bacteria, viruses, mold, mildew, and common air quality irritants. AP/ArmaFlex, AP CoilFlex and AP SpiralFlex products included in our ArmaFlex® range come with Microban antimicrobial protection, and when used as liners inside ventilation ducts, can help prevent the growth of mold and mildew on the insulation. Our AP/ArmaFlex products meet or exceed ASTM and UL requirements for mold, fungi and bacteria resistance. The closed-cell foam structure of our material prevents the wicking of moisture — further reducing the likelihood of mold growth. In addition, the materials have always been 100 percent fiber-free and formaldehyde-free.

Since 2006, Armacell has manufactured foam insulation products made with Microban® antimicrobial product protection – and we were the first foam insulation provider to do so. Microban utilizes built-in antimicrobial technologies to safeguard and help keep products cleaner, fresher, and protected for longer periods of time. Using antimicrobials such as this allows consumers to protect products from bacteria, viruses, mold, mildew, and common air quality irritants. AP/ArmaFlex, AP CoilFlex and AP SpiralFlex products included in our ArmaFlex® range come with Microban antimicrobial protection, and when used as liners inside ventilation ducts, can help prevent the growth of mold and mildew on the insulation. Our AP/ArmaFlex products meet or exceed ASTM and UL requirements for mold, fungi and bacteria resistance. The closed-cell foam structure of our material prevents the wicking of moisture — further reducing the likelihood of mold growth. In addition, the materials have always been 100 percent fiber-free and formaldehyde-free.