Michigan-based converter, Packaging Products Inc., created a successful partnership with Armacell to support their versatile cushioning, packaging, and protection products. From automotive to military applications, our ArmaComp™ component foams solutions helped this customer solve supply chain challenges and tight deadlines.

Michigan-based converter, Packaging Products Inc., created a successful partnership with Armacell to support their versatile cushioning, packaging, and protection products. From automotive to military applications, our ArmaComp™ component foams solutions helped this customer solve supply chain challenges and tight deadlines.

Shipping sensitive materials, important equipment, and heavy objects can be a challenge under regular circumstances. Compounded with normal supply chain difficulties after the COVID-19 pandemic, companies around the world struggled to meet logistical demands. Raw material shortages, long lead times, and missed shipping deadlines impacted almost all industries. Many industries experienced major operational upsets and shipping delays, especially critical ones like the medical, automotive, and military industries. Suppliers to those industries also felt the pressure to meet challenging demands which fostered the need to build stronger relationships and innovative solutions.

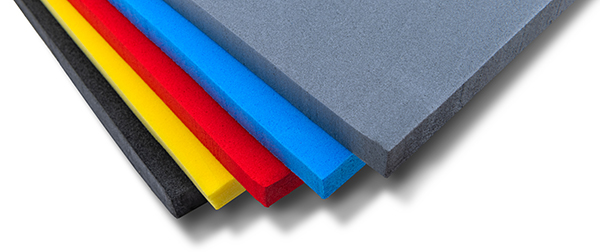

Packaging Products Inc., a leading provider of custom fit foam solutions, supplies foam gasketing, cushioning and packaging products to a variety of customers in automotive, aerospace, the U.S. military, medical, construction, and industrial companies. It provides lamination, sawing, skiving, sheeting, die cutting, and adhesion services and is a minority-owned company.

For over three decades this company has thrived and grown, but they were not shielded from the impact of the pandemic. In 2021, Matt Flory, Vice President of Sales, discussed a challenge of suppling large volumes of material for an automotive project with Brad Soltysiak, Amracell Sales and Marketing Manager. The automotive venture was for General Motors regarding the Chevy Volt EV battery recall program where volatile batteries had to be packaged and shipped to Mexico for processing. Packaging Products Inc., had to procure cross-linked polyethylene closed-cell foam to put inside shipping crates holding the batteries, but the COVID-19 pandemic created strains on suppliers. Soltysiak worked closely with our manufacturing and customer teams to be able to supply the volume needed for Packaging Products to create the custom foam cushioning for safeguarding the batteries. After successfully allocating a steady supply of our OleTex® product within the deadlines required for shipments to Mexico, it was estimated that Armacell supplied over thirty-six full truckloads of our foam buns! Our OleTex product is a versatile cross-linked polyethylene foam developed for a limitless range of creative die cut, heat molded capabilities in automotive, military, construction, packaging, and recreation applications. It can be formulated for soft, flexible applications or in blends that provide stiff, high-compressive-strength end uses. Various blends of Ethylene Vinyl Acetate (EVA) are used to achieve desired flexibility. Additionally, it is offered in buns, continuous rolls, laminated rolls, and sheets that can be sliced to preferred thicknesses. In collaboration with Armacell, Packaging Products Inc., successfully supply their solutions around the world.

Read the full case study here.