Plastic pipes are used frequently in all types of buildings and their market share continues to grow. Plastic piping systems have unique attributes that provide installers flexibility over traditional metal piping systems. They are commonly used as domestic-water and wastewater pipes, as gas pipes for heating and plumbing systems, and increasingly for chilled-water pipes.

Plastic Piping Found in Building Construction

ABS (Acrylonitrile Butadiene Styrene)

ABS (Acrylonitrile Butadiene Styrene)- CPVC (Chlorinated Polyvinyl Chloride)

- PB (Polybutylene)

- PE (Polyethylene)

- PEX (Cross-linked Polyethylene)

- PP (Polypropylene)

- PVC (Polyvinyl Chloride)

- PVDF (Polyvinylidene Fluoride)

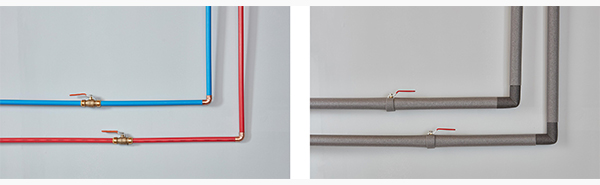

While building occupants may not pay attention to pipes or their type, that will quickly change if there is a leak or system failure. Fortunately, this can be avoided if you take the simple step of having the plastic pipe insulated throughout your building systems. The transition from metal piping systems to plastic systems has led to a major misconception that these materials do not need to be insulated. However, insulation is essential because just like metal pipes, plastic must also be protected against energy loss. Even though plastic pipes have a lower thermal conductivity than metal, properly installed insulation on pipes will reduce heat loss/gain up to 75% when compared to uninsulated pipes.

Beyond thermal protection and energy efficiency, insulation on plastic pipes provides condensation control in high humidity environments, freeze protection in very cold conditions, as well as some acoustic and vibration control. Insulation added to hot water and service hot water lines can also aid in water conservation by allowing hot water to reach the target temperature quickly while maintaining the temperature longer between uses.

In addition to energy efficiency and condensation control, most building codes and standards require piping systems that carry heated or cooled fluids, to be insulated to reduce heat loss/gain or transfer. These codes do not identify types of piping systems that should be insulated, but rather require all piping systems that convey fluids that have been heated or cooled to be insulated based on Fluid Operating Temperature Range and Usage (°F) and pipe diameter. Building codes look at applications and operational criteria when requiring insulation and the targeted thickness to be installed.

Maintaining the integrity and performance is vital over the life of a system and Armacell offers system solutions that incorporate polyethylene and elastomeric insulation products, adhesives, tapes, pipe saddles and pipe supports that can be tailored to performance, code and budget requirements.

For specific code requirements, check the local building codes in your municipality, country, or state.