Rocky Mount High School, Rocky Mount, NC

Elastomeric Foam Duct Liner Meets Acoustic and IAQ Demands of North Carolina High School

Project: Rocky Mount High School

Location: Rocky Mount, NC.

Engineering Firm: Optima Engineering, Charlotte, NC

Acoustical Engineering Firm: Stewart Acoustical Consultants, Raleigh, NC

CHALLENGE: Fiber-free, moisture-resistant sound attenuation for large heat pumps and air handlers of high school’s centralized geothermal system.

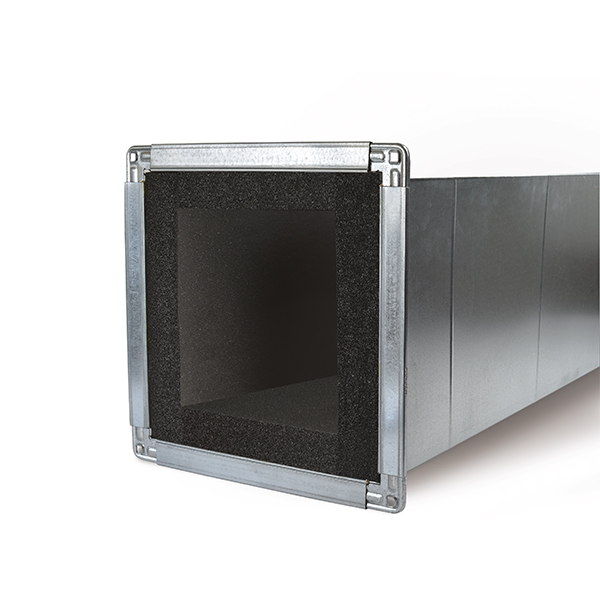

SOLUTION: AP Coilflex elastomeric foam duct liner for the critical space between the supply air and first take-off to each terminal box.

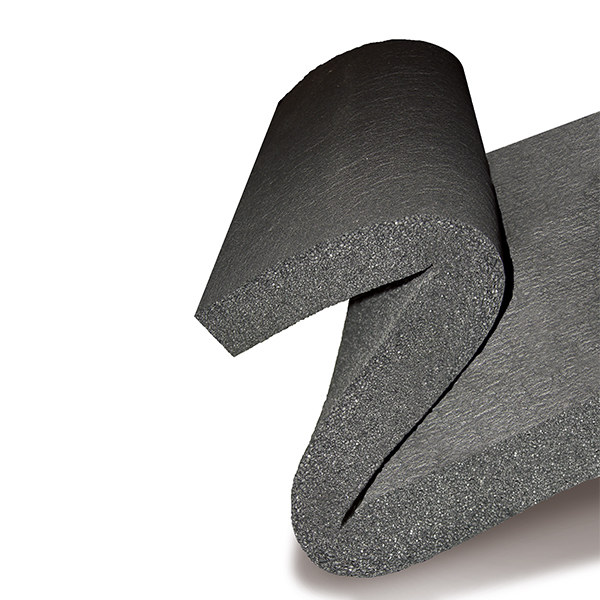

Schools follow certain strategies when it comes to green building. Solar panels, day lighting, and rainwater harvesting systems are common practices these days. In addition to these more obvious strategies, elastomeric foam duct liner is gaining ground for its role in assuring a quiet and fiber-free air delivery system, both of which are important aspects of LEED for Schools. This was the case at Rocky Mount High School, in Rocky Mount North Carolina.

An Efficient Yet Potentially Noisy System

Optima Engineering of Charlotte, NC chose a centralized geothermal system as part of the school’s energy efficiency strategy. Although this was a maintenance friendly choice, it incorporated larger heat pumps and air handlers, which created potential noise problems inside the classrooms. Excessive mechanical vibration and noise would surely result without the sound attenuation of duct liner.

Fibrous duct liner was not an option. Nash County School Board made it clear they wanted a fiber-free, moisture-resistant air delivery system. This led Optima to specify AP Coilflex elastomeric foam ductliner for the critical space between the supply air and first take-off to each terminal (VAV) box. The decision was preceded by some fairly exhaustive research and collaboration with Stewart Acoustical Consultants in Raleigh, NC.

Low Frequency Noise Challenge

Low frequency noise (125 to 500 Hz) is the most difficult type of noise to attenuate in a mechanical system. This noise is typically associated with the throb of turbulent airflow and fan instability, and it was anticipated to be a problem for Rocky Mount High School. After much research and analysis, Joseph Bridger of Stewart Acoustical Consultants suggested AP Coilflex as a suitable solution. AP Coilflex offers superior sound absorption performance at 125 to 500 Hz.

“The reason I chose this liner was because it performs so much better at 500Hz than other cellular liners,” said Bridger. “Other products require much more length to achieve the same sound attenuation.”

It was the perfect solution for this LEED registered school and its high IAQ standards. AP Coilflex is not only fiber-free, it is also formaldehyde free, has low VOC’s, is made with Microban® antimicrobial protection and is GREENGUARD® Children and Schools Certified. (Today AP Coilflex is GREENGUARD GOLD Certified.) It’s also a viable option for projects with challenging budgets because it can be applied to sheet metal duct using automated coiling equipment and does not require dual wall or encapsulation to contain fibers. This makes the installation less costly.

All this is good news for Joseph Bridger, who has seen a significant increase in the number of clients who want to use non-fibrous duct liner. He estimates that half of his projects demand fiber-free ducts.

Download the Job Story PDF here.