Murano Condominiums, Philadelphia, PA

AP Armaflex Provides Moisture Resistant, Cost Effective Solution for High-rise Condominium

Project: Murano Condominiums

Location: Philadelphia, PA

Objectives: Find a non-permeable, cost-effective alternative to foam glass insulation for plumbing and HVAC throughout the 43-story condominium. Minimize risk of mold growth.

Contractor: Tempered Insulation

PROBLEM: The foam glass insulation specified for the plumbing piping in the new Murano high-rise condominium building in center city Philadelphia was cost prohibitive, and would require special tools and protection for workers.

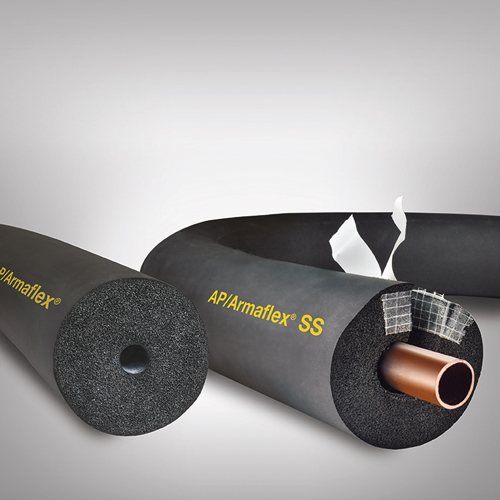

SOLUTION: AP Armaflex SS (SelfSeal) pipe insulation provided an excellent and more installer-friendly alternative. It also met the clients need for a moisture-proof and mold-resistant material.

High rise concrete structures offer excellent thermal efficiency but present a number of challenges during construction, particularly with respect to moisture intrusion. Because these structures tend to be extra tight, it is important that construction crews protect any permeable materials from moisture or rain during the construction process. If, for instance, insulation gets wet and is then installed before it dries, that moisture could lead to mold problems that may go undetected for months or even years.

Moisture intrusion was certainly a concern for the owner of the 43-story Murano condominium. As each level of a poured concrete building is added, there are times when the building is not closed in at the top, leaving the interior exposed to rain. This can cause major delays in construction since workers cannot work with permeable materials under these conditions. Although the original foam glass specification was good for moisture resistance, it presented several other problems for the installers, not to mention great expense for the owner.

“It literally takes the teeth off of a handsaw. It will also wipe off your fingerprints, so you can’t handle it without gloves,” said Art Sweeney, Manager of Tempered Insulation.

Although foam glass resists moisture and is an effective insulation in terms of stopping heat gain or heat loss, said Mr. Sweeney, it makes for a problematic installation which increases cost to the owner.

“The labor would have been astronomical, since it requires so much special equipment like respirators, gloves, eye protection, and special tools.”

Tempered Insulation opted to value engineer the project using AP Armaflex instead of the foam glass. The decision not only saved the client money, but also helped keep construction on schedule.

AP Armaflex SS (Self Seal) pipe insulation was used throughout the high end condominium. This included insulation for all the domestic water piping in the walls and between the floors, which amounted to 60,000 feet of 1/2½-inch self-adhering Armaflex product sold through Insulation Materials Corporation in Aston, PA. Armaflex was also used to insulate the heating hot water, chilled water, and condensate drain piping for the nearly 500 fan coil units installed to heat and cool the individual condos.

Closed-cell AP Armaflex is not only fiber-free, its smooth, non-particulating surface is extremely easy to clean. It is also the only insulation made with Microban® antimicrobial product protection. It can be cleaned and sanitized like any hard surface material, potentially saving facilities thousands of dollars in mold remediation.

Mr. Sweeney had an interest in using the AP Armaflex with the Microban additive since Armacell first started incorporating it into the Armaflex product in 2006.

Increasing concern over mold in buildings fed his interest.

“Problems with mold and mildew have reached almost epidemic proportions in the last few years. The problem has been exacerbated by tighter buildings, as well as demanding building and project management schedules,” said Sweeney.

Using Armaflex allowed Sweeney to keep crews working even in the rain without going to the trouble of securing the building because there was no paper jacket. Had the value engineering involved a paper-jacketed fiberglass instead of closed-cell elastomeric foam, the crew would not have had this flexibility.

Download the Job Story PDF here.