Genencor, A Danisco Division, Rochester, NY

Closed-Cell, Non-Halogen Armaflex Meets Unique Needs for Enzyme Process at Genencor

Project: Genencor, a Danisco Division

Location: Rochester, NY

Objectives: Maintain critical cooling temperatures of 304 Stainless Steel Process tanks while minimizing microbial growth, and preserving structural integrity of tanks and insulation in a challenging process environment.

Mechanical Contractor: Griffin Insulation Co. Inc., Rochester, NY

Distributor: Specialty Products & Insulation Co. Rochester, NY

PROBLEM: Genencor, a company which produces industrial enzymes, was having difficulty maintaining steady temperatures of 10-12°C in four stainless steel process tanks. Thermal insulation was required, but the chemical laden environment ruled out such options such as fiberglass and blown ceramic.

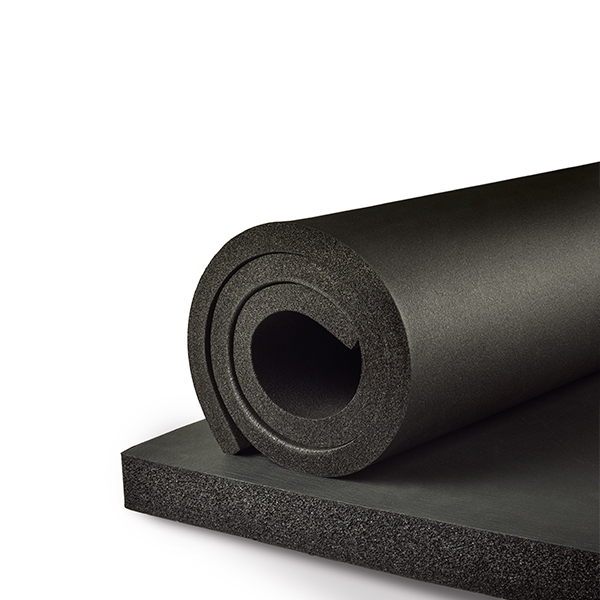

SOLUTION: Closed-cell ArmaFlex provided all the thermal and structural protection Genencor needed. NH/ArmaFlex (Halogen-Free) provided greater reliability in a corrosive environment with large temperature swings.

As in most process applications, temperature and environmental issues are serious considerations for Genencor, a division of Danisco which designs and produces innovative enzymes used by industrial manufacturers around the world.

The company had transferred four 6000 gallon 304 stainless steel tanks to its plant in Rochester to be used for specialized enzyme  production. Because it was critical that the contents of the tanks be maintained at 10-12°C (50–53.6°F) during production, Genencor installed external cooling panels utilizing chilled glycol on the tanks, and installing a heat transfer cement between the panels and steel walls of the tanks to aid cooling efficiency. While they had managed to use the tanks temporarily without insulation, they found that it was very difficult to maintain the temperatures. The process was also imposing large loads on their chiller plant. It was clear that the tanks would have to be insulated; selecting the right insulation for the job was the challenge.

production. Because it was critical that the contents of the tanks be maintained at 10-12°C (50–53.6°F) during production, Genencor installed external cooling panels utilizing chilled glycol on the tanks, and installing a heat transfer cement between the panels and steel walls of the tanks to aid cooling efficiency. While they had managed to use the tanks temporarily without insulation, they found that it was very difficult to maintain the temperatures. The process was also imposing large loads on their chiller plant. It was clear that the tanks would have to be insulated; selecting the right insulation for the job was the challenge.

Process engineer Adam Shanebrook and Jay Griffin of Griffin Insulation appreciated the structural integrity and flexibility that ArmaFlex closed-cell insulation provided. Both knew there was a chance that the tank insulation might require repair or alternations one day; he was also aware that accidental cuts or punctures could occur. If he chose an open cell insulation such as fiberglass, these cuts or punctures would leave the insulation vulnerable to moisture intrusion and harsh chemicals. Since closed-cell Armaflex does not absorb moisture of any kind, proper installation ensures that neither moisture nor process chemicals would penetrate the insulation. This is the case even without the vapor barrier that is required by fibrous glass insulations.

Ease and speed of installation were also important. While blown ceramic insulation offered closed-cell protection and was chemically resistant, installing the material would interrupt plant production. Installing fiberglass would also present challenges since the production materials would have to be safely isolated from exposure to fibers.

“Using ArmaFlex made it much easier for us to execute the installation without upsetting Genencor’s production schedule,” said Jay Griffin of Griffin Insulation Company, Inc., a company that prides itself on value-added services and attention to detail. “Their production team worked closely with us on timing so that we were able to work on one tank while the other tanks were in full operation. It was good teamwork all around.” The material was supplied to Griffin by Specialty Products & Insulation Co.

Given these concerns, ArmaFlex seemed to be the perfect choice. Simple calculations assured that ArmaFlex would provide the thermal efficiency required for the application.

For all stainless steel applications above 125°F (52°C) Armacell  recommends a specialized closed cell product: NH/ArmaFlex (non-halogen), originally developed for demanding marine applications.

recommends a specialized closed cell product: NH/ArmaFlex (non-halogen), originally developed for demanding marine applications.

Although Genencor’s typical process temperatures were much lower than this, wash down temperatures exceeded 125°F, necessitating a non-halogen product.

“We always offer NH/ArmaFlex on any stainless steel application over 125 degrees Fahrenheit,” said Robert Dizel, Sales & Market Manager for Armacell.

According to Dizel, all stainless steel systems are susceptible to transcrystalline stress corrosion, especially at temperatures over 125°F. Armacell developed NH ArmaFlex with these particular applications in mind. NH/ArmaFlex contains no chlorides, bromides or fluorides. At the same time, NH/ArmaFlex has very good water vapor transmission and thermal properties. As an extra precaution, Mr. Shanebrook conducted tests to evaluate NH/ArmaFlex’s resistance to various chemicals used in the Genencor process. These chemical tests included 100% ethanol, 10% sodium hydroxide/90% water (pH 13.9), and 100% Glacial Acetic Acid (pH 1.77). He placed 2 x 4 samples of NH/ArmaFlex in these solutions at room temperature for 16 hours, after which he personally examined them for signs of degradation.

“None of the samples showed any sort of reaction to the chemicals,” said Mr. Shanebrook. “No discoloration, no loss in mechanical strength or change in texture was seen.”

The NH/ ArmaFlex was installed at the Genencor plant in March of 2007, by Griffin Insulation. After 4 to 5 months of operation, Mr. Shanebrook confirms that the product has thoroughly met their expectations in terms of durability and thermal performance. Furthermore, by maintaining consistently low process temperatures, Genencor has reduced the number of routine filtration measures required to keep contaminate counts sufficiently low. To this end, ArmaFlex is not only ensuring accurate process work, it is helping to eliminate some labor.

“The NH/ArmaFlex is an excellent product for demanding process applications,” said Robert Dizel. “NH has primarily been used in marine applications for 15 years or so and continues to provide long term protection for demanding needs. NH also provides unique protection for demanding Industrial and Commercial applications such as Genencor’s stainless steel applications.”

Download the Job Story PDF here.