Garrett A. Morgan Water Pump Station, Cleveland, Ohio

Water Water Everywhere, But Not a DROP of Condensation!

Project: Garrett A. Morgan Water Pump Station

Location: Cleveland, Ohio

Insulation Contractor: Berry Pipe and Equipment Insulation Company

PROBLEM: High potential for condensation in pump station pipe gallery makes insulation critical. Because the pump station is adjacent to a historic landmark, appearance is a high priority.

SOLUTION: AP Armaflex provides moisture resistance, ease of installation, and a smooth, paintable surface for overall appearance.

It’s not often that historic charm and municipal water processing go hand-in-hand. However, the city of Cleveland, along with an army of engineers, architects, and contractors made sure that the Garrett A. Morgan Water Pump Station maintained its historical integrity during construction of a new pump station. Beneath its quaint tiled roof, 150-million gallons of water are processed daily. Filtered, chlorinated water from Lake Erie enters the basement of the building through massive 96-inch pipes. From there it is pumped through a series of branch piping, providing “finished water” to every corner of the city.

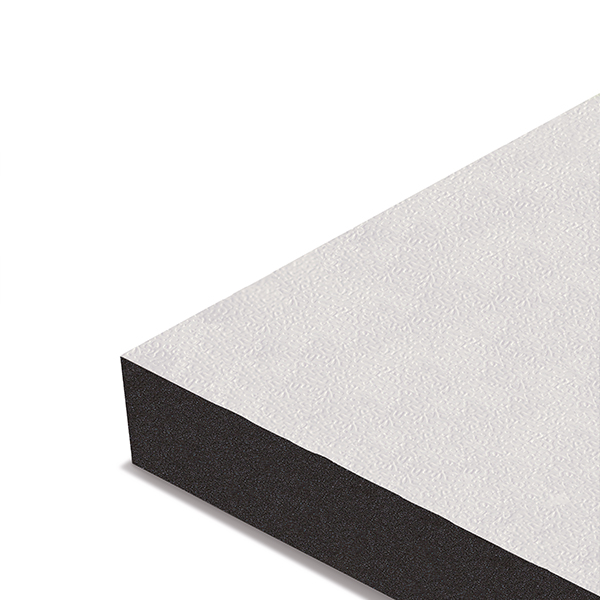

“It’s a recipe for a lot of condensation,” says Jim Lada, Project Engineer for National Engineering & Contracting (the general contractor). “Reliable insulation was an important component in protecting the physical integrity of this building which had been so carefully designed to replicate the look and feel of the original circa 1900 plant. The engineering team knew they wanted closed-cell foam insulation due to its inherent ability to prevent condensation...” Following the advice of Berry Pipe & Equipment Insulation Company, AP Armaflex sheets were selected for the project. Armaflex is the original closed-cell elastomeric foam insulation.

Commonly selected as the optimum insulation for cold water applications, AP Armaflex was the ideal choice for this project with its high potential for condensation. Its protection is two-fold:

1. Armaflex keeps the pipe surface temperature above dew point, so condensation will not form.

2. Armaflex’s closed-cell structure prevents any moisture wicking from occurring, therefore preventing the conditions that lead to mold or mildew.

In all, 140 rolls of 4 ft. wide, 1-inch thick AP Armaflex foam insulation were installed on the 8 ft. pipe that feeds the pump station. The sheets were installed on the pipe using adhesive rollers and Armaflex 520 Adhesive. The roller method, suggested by the Armacell regional manager, helped facilitate the installation. The large sized sheets also minimized the number of joints the installers had to make while installing the insulation. Although painting is not typically required for indoor installations, the owner chose to coat the insulation with WB Armaflex Finish, tinted to match the Safety Blue piping in the station basement.

“It looks very nice,” remarked Mr. Lada. “Berry made a good suggestion with this product and they did a great job with the installation.”

In fact, some recent innovations from Armacell would have provided additional alternatives for this installation. The company has introduced Armaflex Low VOC Spray Contact Adhesive as a much faster, easier, cleaner alternative to the traditional roller method for applying adhesive to sheets.

In fact, some recent innovations from Armacell would have provided additional alternatives for this installation. The company has introduced Armaflex Low VOC Spray Contact Adhesive as a much faster, easier, cleaner alternative to the traditional roller method for applying adhesive to sheets.

In addition, ArmaTuff products can provide excellent, maintenance-free alternatives to painting.

For large surfaces like tanks, vessels and larger pipes, ArmaTuff sheets and rolls are suitable for all-weather applications. It’s Armaflex insulation laminated with a 12 mil heavy duty embossed metal cladding that is extremely resistant to tears and punctures, and requires no painting.

Download the Job Story PDF here.