Why Insulate Cold Systems?

Choose AP ArmaFlex, the Right Insulation for Cold Systems

PREVENTS MOISTURE INTRUSION AND ITS CONSEQUENCES

Insulation is typically seen as a means to prevent heat gain or loss through the building envelope. Yet energy-efficient design also must address all interior piping and air-handling systems – with the right insulation materials in the right thicknesses. These mechanical systems particularly benefit from insulation’s ability to prevent condensation, moisture intrusion and longer-term problems. Moisture from condensation is a problem in any cold system. Too frequently, it is assumed that all insulations are equally suitable for any insulation application. However, this generalization is wrong for cold systems and can lead to system failure, call-backs, energy waste, even mold and building closings. Not every insulation option is engineered for cold applications, but AP ArmaFlex closed-cell elastomeric foam is. And while specifying a single insulation material for an entire project may be convenient, it may be a real mistake when cold systems are part of the mix.

The Nature and Cause of Condensation

Water vapor is naturally attracted from warmer ambient air to cold surfaces. The water vapor in the air changes to liquid (condensates) at the cooler surface. This same physics applies to cold-water piping. If the temperature surrounding the piping drops below the dew point, condensation will form on the pipes. The presence of moisture not only robs the system of its thermal efficiency, but it also provides suitable conditions for corrosion, moisture damage, or mold and mildew. Without adequate insulation or the right insulation, condensation will form on the pipe.

No Jacket Required: The Value of Closed-Cell Protection

The optimum preferred insulation to prevent moisture intrusion has a closed-cell structure. The most frequently selected alternative option is open-cell fibrous insulation, which requires a separate vapor retarder, or jacket, that can fail when it is punctured or torn. Open-cell material has a non-connecting, random cellular structure. Its porous cells have no walls and cannot block moisture migration or wicking inside the insulation.

Once the jacket is damaged, fibrous insulation may become wet, losing all its thermal properties as well as creating the ideal condition for mold and poor air quality.

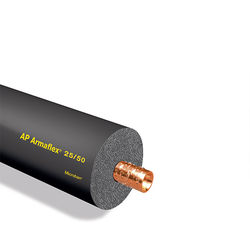

Closed-cell foam insulation like AP ArmaFlex has a non-interconnected cellular structure. It is not porous because cells have sealed walls that inhibit moisture migration or wicking inside the insulation. The multi-layered structure cannot be compromised by surface punctures or tears. It’s like having a vapor retarder built right in.

moisture migration or wicking inside the insulation. The multi-layered structure cannot be compromised by surface punctures or tears. It’s like having a vapor retarder built right in.

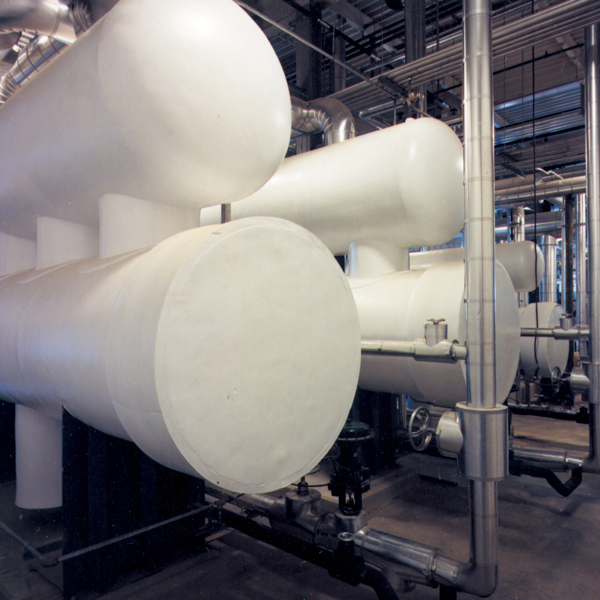

AP ArmaFlex elastomeric foam is a closed-cell material that’s ideal for chilled-water systems when properly installed… without a separate, fragile vapor retarder.

The theory of condensation control is really quite simple: You must maintain the surface temperature above dew point temperature. Dew point is the point at which saturated air starts to condense. It is a measure of how much water vapor is actually in the air; the warmer the air is the more water vapor it can hold. Relative humidity is a measure of the amount of water in the air compared with the maximum amount of water the air can hold at the current temperature. As the amount of water vapor increases at a given temperature, relative humidity increases. An increase in temperature increases the Dew Point and the Relative Humidity.

Moisture Control Is Critical to Thermal Efficiency

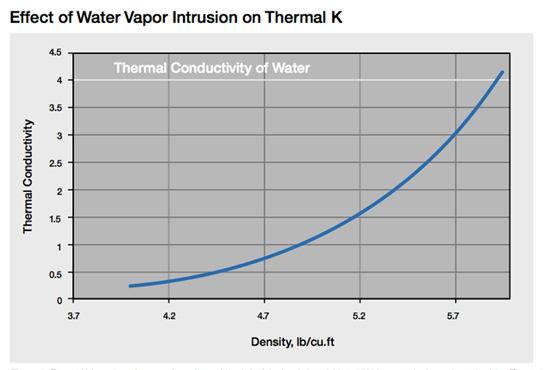

If moisture intrudes the insulating material surrounding cold-water piping, thermal efficiency is lost. For every 1% in moisture gain, there is a 7.5% loss in thermal efficiency. In other words, a single percent increase in moisture equates to a 7.5% increase in thermal conductivity (Thermal k) — or the transference of heat from one surface to another. With chilled-water systems, this condition leads to energy loss and higher operating costs. Figure 1 shows the effect of water vapor intrusion on Thermal k.

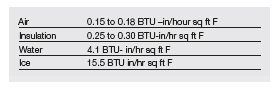

To better understand thermal conductivity, consider the comparative thermal conductivities of the following:

The impact of moisture on thermal performance is obvious when comparing the thermal conductivity of water to insulation.

The thermal conductivity of water is approximately 13 times greater than insulation. Therefore, heat transfer from the air to the chilled-water pipes greatly increases when insulation gets wet.

The heat gain of the chilled-water pipes equates to loss of costly cooling BTUs.

The cooling system will work harder to compensate for the loss in efficiency and possibly reduce the service life of the system.

Effect of Water Vapor Intrusion on Thermal K

Figure 1: Every 1% by volume increase in moisture (density) of the insulation yields a 7.5% increase in thermal conductivity. Thermal conductivity of water equals 4, the point of total saturation of the insulation material. When the vapor jacket of open-cell insulation is damaged, the insulation can relatively quickly reach saturation due to wicking... and result in very high thermal k values.

Moisture Control Is Critical to IAQ and Problem-Free Facility Operations

Moisture intrusion due to compromised insulation systems also creates conditions favorable to mold and mildew. Because mold is a common allergen, the problem of mold contamination cannot be ignored. Mold can grow unseen behind walls and in plenums. The spores spread easily, even more so if present in air-handling systems. Contamination has caused school and building closings throughout the U.S. and costly litigation for many in the construction industry.

Mold requires three key conditions: Moisture, a food source and the right temperatures. (Read More About Mold link)

Condensation can provide sufficient moisture for mold spores to germinate. Wet pipes or wet insulation can contribute enough moisture for mold growth in existing buildings.

Mold needs little more than dust and dirt as food sources – or the cellulose kraft paper in vapor jackets on some insulation materials.

The final primary requirement, 40°F to 100°F temperature, is nearly always present inside buildings, so the other two factors must be controlled.

Practice Condensation Control

Maintain the surface temperature above the dew point.

Select closed-cell foam insulation: ArmaFlex is the closed-cell elastomeric insulation invented to prevent condensation, moisture intrusion and loss of thermal efficiency.

Use the Armacell ArmaWin program to calculate the insulation thickness needed to maintain the surface temperature above the dew-point temperature.

AP ARMAFLEX: The Original Closed-Cell Solution

Prevents Moisture Intrusion

Excellent resistance to Water Vapor Transmission: Low 0.08 WVT

Provides Long-Term Thermal Performance

Non-wicking: Moisture will not migrate through properly installed ArmaFlex

Provides Long-Term Durability: No Fragile Vapor Jacket

Acts as its own vapor retarder

Multi-layered closed wall cells can’t be compromised by surface punctures or rips

Withstands abuse during installation

Keeps working: Stands up to ongoing maintenance work after building occupancy

Helps prevent callbacks, product replacement and costly closings

Inhibits Growth of Mold and Mildew

Minimizes moisture intrusion, the first requirement for mold growth

Minimizes the second requirement: No cellulosic vapor jacket and the smooth surface doesn’t trap dust and is easy to clean

Made with Microban® antimicrobial protection to further resist the growth of mold

Provides Other IAQ Benefits:

Fiber-free: Won’t add fibers to the air stream

Clean: Dust-free, dirt-free, non-particulating – spaces can remain occupied during renovation work

Formaldehyde-free: Always has been!

Low VOCs: Plus, no off-gassing, which means faster building occupancy

Environmentally friendly manufacturing: No CFCs or HCFCs

GREENGUARD Gold Certified to low chemical emissions into indoor air when the product is in use