Gaskets can be defined as components used to help seal joints, limit vibration, and prevent leaks. When looking for the best gasket for an application, consumers can get overwhelmed by the variety of choices in the market. There are several different material compositions, foam attributes, and specific requirements to take into consideration when trying to seal and secure a system. Here is a quick guide on the types of foam typically used in gasketing applications and how Armacell can help you!

Gaskets can be defined as components used to help seal joints, limit vibration, and prevent leaks. When looking for the best gasket for an application, consumers can get overwhelmed by the variety of choices in the market. There are several different material compositions, foam attributes, and specific requirements to take into consideration when trying to seal and secure a system. Here is a quick guide on the types of foam typically used in gasketing applications and how Armacell can help you!

- Open-Cell Foam has its cells ruptured, so it takes on a light and adaptable form. This type of foam has a very low compression set resistance, which means that when compressed with a load, it will return quickly to near its original form and thickness. This can be useful for products that need to adapt to an uneven surface or see heavy, repeated use.

- Closed-Cell Foam has cells that are expanded, but still individually intact. Closed-cell foam has a high compression set values than open-cell foam. When compressed under a load for long periods, closed-cell foams will not regain their total original thickness. Closed-cell foams have excellent resistance to water absorption so if an application needs both strength and moisture resistance, then a closed-cell foam is the better choice.

- Semi Closed-Cell Foam, also known as crushed foam, is a hybrid of sorts that fits between open-cell and closed-cell foams. Semi closed-cell foams are highly flexible, so they excel at sealing irregular surfaces at high compression percentages.

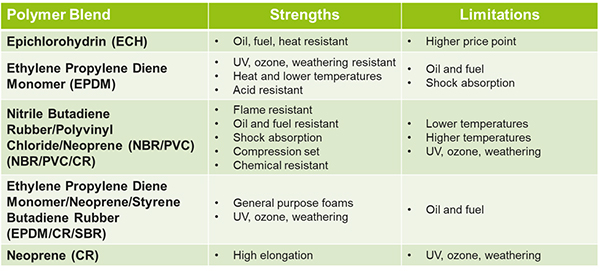

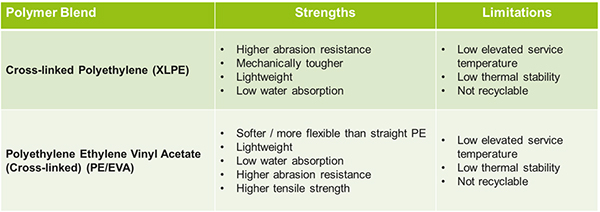

Now that you are familiar with these three types of cellular materials typically used in gasketing applications, it is time to review the different polymer compositions. Our Component Foam division manufactures two categories of products: Elastomeric Component Foams (ECF) and Polyolefin Component Foams (PCF). ECF products are based on various synthetic polymers such as NBR/PVC, EPDM, Neoprene (CR), ECH, and EPDM/CR/SBR blends. ECF products are high-performance foams offered in many formulations to meet different physical properties and chemical resistance requirements. Crosslinked PCF products are made from thermoplastic polymers and can be formulated into many different densities and firmnesses that are suitable for a wide variety of applications. Below are two comparison charts.

Now that you are familiar with these three types of cellular materials typically used in gasketing applications, it is time to review the different polymer compositions. Our Component Foam division manufactures two categories of products: Elastomeric Component Foams (ECF) and Polyolefin Component Foams (PCF). ECF products are based on various synthetic polymers such as NBR/PVC, EPDM, Neoprene (CR), ECH, and EPDM/CR/SBR blends. ECF products are high-performance foams offered in many formulations to meet different physical properties and chemical resistance requirements. Crosslinked PCF products are made from thermoplastic polymers and can be formulated into many different densities and firmnesses that are suitable for a wide variety of applications. Below are two comparison charts.

ECF Comparison

PCF Comparison

Gasket and Sealing Product Solutions

Gasket and Sealing Product Solutions

Armacell has the expertise to create cellular materials in sheets, rolls, and buns for foam converters and fabricators that supply gasketing and sealing products. Understanding specific performance standards, foam composition, and specification requirements can help you select the best product for your application. Many of our solutions are tested to and meet ASTM, UL, or industry specific specifications and standards. Armacell's EnsoLite®, Monarch® and OleTex® products are used in a wide range of mechanical and industrial sealing and gasketing solutions. Monarch products are closed-cell polymeric buns primarily made of 100% EPDM, ECH, EPDM/CR/SBR blend, NBR/PVC, and CR. EnsoLite products are closed-cell rolls based on PVC/NBR, PVC/NBR/CR, EPDM or CR polymers. The EnsoLite brand includes semi-closed cell foams manufactured from PVC/NBR or EPDM. OleTex products are a chemically cross-linked and highly versatile polyolefin foam made from blends of PE or PE/EVA. Check out our component foam product selector tool for more help.

Armacell has the expertise to create cellular materials in sheets, rolls, and buns for foam converters and fabricators that supply gasketing and sealing products. Understanding specific performance standards, foam composition, and specification requirements can help you select the best product for your application. Many of our solutions are tested to and meet ASTM, UL, or industry specific specifications and standards. Armacell's EnsoLite®, Monarch® and OleTex® products are used in a wide range of mechanical and industrial sealing and gasketing solutions. Monarch products are closed-cell polymeric buns primarily made of 100% EPDM, ECH, EPDM/CR/SBR blend, NBR/PVC, and CR. EnsoLite products are closed-cell rolls based on PVC/NBR, PVC/NBR/CR, EPDM or CR polymers. The EnsoLite brand includes semi-closed cell foams manufactured from PVC/NBR or EPDM. OleTex products are a chemically cross-linked and highly versatile polyolefin foam made from blends of PE or PE/EVA. Check out our component foam product selector tool for more help.

If you are looking for a gasket that will retain its shape, recover after extended use and is conformable to varying shapes, then an open-cell foam is a great place to start. If you need strength as well as good sealing against air, dust and water, then a closed-cell foam will fit your needs. If you are looking for a happy medium between the two that is better suited for irregular surfaces, then crushed foam will be a good material to investigate. Ultimately, whatever foam you end up choosing for your next project will come down to what you specifically need for the application and any associated requirements. With all that in mind, the next time you need to make a buying decision for foam gaskets, you can utilize this guide to make the most informed and practical decision.

If you are looking for a gasket that will retain its shape, recover after extended use and is conformable to varying shapes, then an open-cell foam is a great place to start. If you need strength as well as good sealing against air, dust and water, then a closed-cell foam will fit your needs. If you are looking for a happy medium between the two that is better suited for irregular surfaces, then crushed foam will be a good material to investigate. Ultimately, whatever foam you end up choosing for your next project will come down to what you specifically need for the application and any associated requirements. With all that in mind, the next time you need to make a buying decision for foam gaskets, you can utilize this guide to make the most informed and practical decision.

Engineered for success

Armacell makes component foams that meet many industry standards. Our fast-responding technical experts will help you navigate our vast product line for any application or develop innovative solutions to meet market requirements.