Moisture from condensation is a potential problem in any HVAC system. Cold water systems, including refrigeration lines, air conditioning lines and chilled water piping are no exception. While HVAC professionals have long applied closed-cell elastomeric foam insulation to ductwork because of its excellent moisture control properties, many are realizing its usefulness in cold water piping. Wet insulation exacerbates heat gain and therefore robs these systems of their efficiency. Because closed cell foam is impervious to moisture, it is a more sustainable and efficient insulating material.

Moisture from condensation is a potential problem in any HVAC system. Cold water systems, including refrigeration lines, air conditioning lines and chilled water piping are no exception. While HVAC professionals have long applied closed-cell elastomeric foam insulation to ductwork because of its excellent moisture control properties, many are realizing its usefulness in cold water piping. Wet insulation exacerbates heat gain and therefore robs these systems of their efficiency. Because closed cell foam is impervious to moisture, it is a more sustainable and efficient insulating material.

The Nature and Cause of Condensation

Water vapor is naturally attracted from warmer ambient air to cold surfaces. The water vapor in the air changes to liquid condensation at the cooler surface. Essentially, as the air cools around the cold surface, it loses its capacity to hold water in a vapor state. Water vapor changes to liquid when the temperature falls below the dew point. The same physics applies to cold water piping. If the temperature surrounding the piping drops below the dew point, condensation will form on the pipes. The presence of moisture not only actually robs the system of its thermal efficiency; it provides suitable conditions for mold and mildew. Without adequate insulation or the right insulation, the system will achieve equilibrium on the pipe surface resulting in condensation on the pipe.

Why Moisture Control is Critical to Efficiency

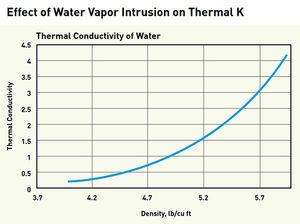

If moisture intrudes the insulating material surrounding cold water piping, efficiency is lost. As explained below, this can happen especially with open cell insulations when their separate vapor retarders are damaged or otherwise compromised. For every 1% moisture gain, there is a 7.5% loss in thermal efficiency. In other words, a single percent increase in moisture equates to a 7.5% increase in thermal

If moisture intrudes the insulating material surrounding cold water piping, efficiency is lost. As explained below, this can happen especially with open cell insulations when their separate vapor retarders are damaged or otherwise compromised. For every 1% moisture gain, there is a 7.5% loss in thermal efficiency. In other words, a single percent increase in moisture equates to a 7.5% increase in thermal

conductivity (thermal k) — or the transference of heat from one surface to another — a condition that one wants to avoid in chilled water systems, as it leads to energy loss and higher operating cost.

Why Closed-Cell Structure Offers Superior Protection Against Condensation

The fact that closed-cell structures are inherently durable and virtually impermeable to water means better lifetime efficiency. This is recognized in ASHRAE Fundamentals 2017 which suggests that cold systems be protected through the use of very low permeance insulating material with a water vapor transmission rate (WVT) of 0.10 per inches or less. (ArmaFlex has a very low WVT of only 0.05). Permeability is defined as the amount of water vapor that passes through a unit thickness of material (typically one inch) over a given period of time under standard pressure.

Closed-cell elastomeric foam, specifically ArmaFlex, has a very low permeability rating, and therefore Selecting closed-cell elastomeric foams is one sure way to prevent moisture (and therefore heat gain) from invading the piping system. Not only does our closed-cell material possess a low permeability rating, it is much less vulnerable to punctures and tears that can render other forms of insulation, specifically open cell materials, ineffective.

For more information or to read the full white paper, click here.