Insulation is typically seen as a means to prevent heat gain or loss. Energy-efficient building design must address interior piping systems and specify the right insulation materials in the right thicknesses. These mechanical systems particularly benefit from insulation’s ability to prevent condensation, moisture intrusion and system failures. Too frequently, it is assumed that all insulation is equally suitable for any application. However, cold and hot pipe systems need different attention and improper specifying can lead to system failures, energy waste and even building closures.

Insulation is typically seen as a means to prevent heat gain or loss. Energy-efficient building design must address interior piping systems and specify the right insulation materials in the right thicknesses. These mechanical systems particularly benefit from insulation’s ability to prevent condensation, moisture intrusion and system failures. Too frequently, it is assumed that all insulation is equally suitable for any application. However, cold and hot pipe systems need different attention and improper specifying can lead to system failures, energy waste and even building closures.

Cold vs. Hot

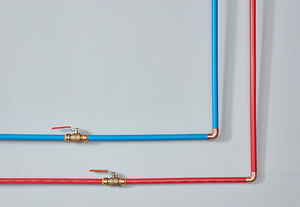

Insulating water supply pipes in exposed areas, especially in cold climates, it is imperative to design efficiency. Any water supply pipes that are exposed to exterior walls or unheated spaces can freeze, burst, and flood a building. Insulating cold water pipes can also prevent the pipes from sweating due to moisture condensation. Moisture control is critical to thermal efficiency and chilled-water systems. An excess of condensation can lead to energy loss, higher operating costs and even poor IAQ due to mold and mildew.

Insulating hot water pipes can save money on energy costs by preventing piping from losing heat to the surrounding air. Insulating hot water pipes can also raise water temperature 2°F–4°F hotter than uninsulated pipes can deliver, allowing a lower water temperature setting. Residents or occupants of a building have an added benefit of not waiting as long for hot water from a faucet, which can help conserve water.

Where and When to Insulate

If the goal is to prevent frozen water pipes and condensation, then the critical pipes to protect are those that run through unheated spaces in places like mechanical rooms, exterior walls, unheated storage buildings, floor cavities above unheated crawl spaces, or even attics or basement spaces. In some cases, heat tracing is necessary for additional freeze protection in addition to insulation.

If the goal is to lower water-heating costs, then it is critical to insulate hot water pipes wherever there is access to them in a building. If the goal of pipe insulation is to eliminate pipe sweating and mold issues, then cold water pipes are in the most need of insulation.

Installing Insulation Recommendations from “The Spruce”

A common product to consider is tubular foam pipe insulation. This product is convenient when longer runs of straight pipe need to be covered. Most foam pipe insulation is available in 6-foot lengths so that you can cover a lot of ground quickly. The tubes can be made of either PE foam or rubber-based insulation, and both are available in many different diameters for different pipe sizes. With regular tubes that require slitting and gluing, or self-seal options, installing foam pipe insulation is one of the simplest of all insulation options.

A common product to consider is tubular foam pipe insulation. This product is convenient when longer runs of straight pipe need to be covered. Most foam pipe insulation is available in 6-foot lengths so that you can cover a lot of ground quickly. The tubes can be made of either PE foam or rubber-based insulation, and both are available in many different diameters for different pipe sizes. With regular tubes that require slitting and gluing, or self-seal options, installing foam pipe insulation is one of the simplest of all insulation options.

Another way to insulate piping, especially for short sections or tight bends is to use a pipe wrap or tape material. Made of flexible foam with a self-adhesive backing, you simply wrap the pipe, fitting or valve with the tape generously overlapping the layers, building up to an appropriate thickness to provide the thermal performance needed.

The Right Product for the Job

For many residential plumbing applications a PE pipe insulation product like Tubolit® and Tundra® is the perfect option. Economical and easy to install, PE foam insulation will prevent pipes from freezing and keep hot pipes hot and cold pipes cold. Tundra can be found at many retail hardware stores for the DIYer and Tubolit is the commercial brand for plumbing and refrigeration pros.

For many residential plumbing applications a PE pipe insulation product like Tubolit® and Tundra® is the perfect option. Economical and easy to install, PE foam insulation will prevent pipes from freezing and keep hot pipes hot and cold pipes cold. Tundra can be found at many retail hardware stores for the DIYer and Tubolit is the commercial brand for plumbing and refrigeration pros.

ArmaFlex® tubes and ArmaFlex® Black LapSeal are closed-cell rubber based tubular pipe insulation for professional use. Flexible and easy-to-install, ArmaFlex is the original foam insulation and still a top solution for all kinds of piping under +220°F (104°C). ArmaFlex tubes save energy and prevent condensation. ArmaFlex® Shield flexible foam insulation is a moisture-resistant and UV-resistant product with a durable protective jacket specially designed for line set, HVAC and refrigeration applications. This tough coating can take the abuse of challenging installations and stands up to the effects of weather and extreme elements like UV, heat and cold, making it a great choice for outdoor applications. ArmaFlex Shield® meets the IECC code and ASHRAE standard 90.1 requirements so it is an excellent commercial choice when selecting outdoor insulation. This low-maintenance alternative to unprotected insulation comes in coils for easy installation and also eliminates the need for adding a separate jacket while on a jobsite.

For more information or to read the full article visit: https://www.thespruce.com/water-pipe-insulation-2718695