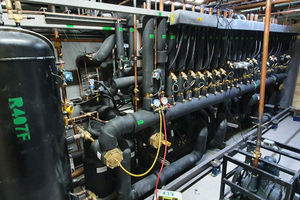

Refrigerant pipe insulation is a critical component of a high-performance refrigeration system. These below-ambient systems vary by application, temperature requirements, refrigerant types, and operating environments. Common refrigeration systems include cold storage, food processing applications, supermarket refrigerators and freezers, laboratory climate controlled environments, and data center cooling systems. Regardless of the location or application, commercial and industrial refrigeration systems are demanding and designed to operate 24/7 in typically the 20°F to -50°F range. These chilled continuous service temperatures are a constant target of moisture causing surface condensation and vapor permeation. Condensation is a refrigerant system’s enemy and can cause decreased thermal efficiency, pipe corrosion under insulation, icing, mold or mildew growth, system failure and most importantly system downtime.

Refrigerant pipe insulation is a critical component of a high-performance refrigeration system. These below-ambient systems vary by application, temperature requirements, refrigerant types, and operating environments. Common refrigeration systems include cold storage, food processing applications, supermarket refrigerators and freezers, laboratory climate controlled environments, and data center cooling systems. Regardless of the location or application, commercial and industrial refrigeration systems are demanding and designed to operate 24/7 in typically the 20°F to -50°F range. These chilled continuous service temperatures are a constant target of moisture causing surface condensation and vapor permeation. Condensation is a refrigerant system’s enemy and can cause decreased thermal efficiency, pipe corrosion under insulation, icing, mold or mildew growth, system failure and most importantly system downtime. By installing the right refrigerant pipe insulation, users can reduce heat gain of refrigerant fluids and control surface condensation. But which pipe insulation is best? First, understanding national and state energy standards, regulations, and conservation codes is critical for building designers. These energy saving requirements are outlined in the International Energy Conservation Code® (IECC) and ANSI/ASHRAE/IESNA1 Standard 90.1. Both provide guidelines for designing residential and commercial buildings and include the requirement for refrigerant pipe insulation on cooling systems that operate with service temperatures below 40°F and up to 60°F. The ASHRAE Handbook specifically recommends closed-cell insulation for refrigeration system applications, such as cellular glass, flexible elastomeric, polyisocyanurate, and polystyrene. While these insulation products share a few characteristics, flexible elastomeric refrigerant pipe insulation is the best solution due to its flexibility, low permeability rating, built-in vapor retarder, thermal integrity, resistance to punctures, and ease of installation.

By installing the right refrigerant pipe insulation, users can reduce heat gain of refrigerant fluids and control surface condensation. But which pipe insulation is best? First, understanding national and state energy standards, regulations, and conservation codes is critical for building designers. These energy saving requirements are outlined in the International Energy Conservation Code® (IECC) and ANSI/ASHRAE/IESNA1 Standard 90.1. Both provide guidelines for designing residential and commercial buildings and include the requirement for refrigerant pipe insulation on cooling systems that operate with service temperatures below 40°F and up to 60°F. The ASHRAE Handbook specifically recommends closed-cell insulation for refrigeration system applications, such as cellular glass, flexible elastomeric, polyisocyanurate, and polystyrene. While these insulation products share a few characteristics, flexible elastomeric refrigerant pipe insulation is the best solution due to its flexibility, low permeability rating, built-in vapor retarder, thermal integrity, resistance to punctures, and ease of installation.

ArmaFlex elastomeric pipe insulation is the right choice and should be specified and installed because:

Low water absorption and low water vapor transmission

- Protection of Indoor Air Quality: Low VOC, fiber-free, non-particulating, formaldehyde-free

- GREENGUARD Gold Certified

- FM Approvals

- Microban® antimicrobial product protection inhibits the growth of mold and mildew

- Closed cell prevents moisture wicking and eliminates need for additional vapor retarder

- Flame and Smoke Developed Index per ASTM E 84 25/50 rated up to 2” wall

- Long-lasting, retains thermal integrity over time

- Available in pre-cut tubes, sheets, rolls, and accessories

Key recommendations for successful elastomeric pipe insulation performance:

Specify the correct insulation thickness: use ArmWin professional insulation thickness calculator

Specify the correct insulation thickness: use ArmWin professional insulation thickness calculator- Specify a UV protective coating for exterior applications to prevent degradation

- Specify a protective jacket product for both weather and mechanical protection when installed in exterior environments

- Specify pipe support saddles to prevent insulation compression at pipe hanger locations: Insuguard saddles and ArmaFix® Ecolight pipe support inserts.

- Seal insulation seams and terminations with a high-performance adhesive to provide a complete vapor seal

Closed-cell elastomeric insulation like AP ArmaFlex®, provides superior protection against thermal losses, condensation, and moisture accumulation. It is the ideal choice for insulating refrigeration piping systems, and it is especially valuable where condensation might otherwise soak through fibrous types of insulation, significantly degrading their thermal performance and ultimately shortening their lifecycle.