Safety standards and their related testing procedures are developed for buildings and their associated systems and components to ensure adherence to minimum requirements to reduce risk and injury. There are several organizations, such as The International Code Council (ICC) and ASHRAE, which develop model building codes and performance standards from both expert and public input. Every state then adopts a model code and corresponding standards, with or without amendments, to be enforced through local code enforcement officials. Typically, state adoptions and local enforcement lag behind the model codes releases by 3 to 9 years giving manufacturers, engineers, contractors and oversight agencies time to ensure products, designs, and industry training are properly in place and available.

Safety standards and their related testing procedures are developed for buildings and their associated systems and components to ensure adherence to minimum requirements to reduce risk and injury. There are several organizations, such as The International Code Council (ICC) and ASHRAE, which develop model building codes and performance standards from both expert and public input. Every state then adopts a model code and corresponding standards, with or without amendments, to be enforced through local code enforcement officials. Typically, state adoptions and local enforcement lag behind the model codes releases by 3 to 9 years giving manufacturers, engineers, contractors and oversight agencies time to ensure products, designs, and industry training are properly in place and available.

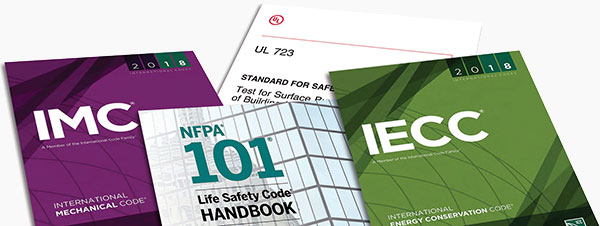

The model building codes from the ICC have long required that all insulation installed on a duct or anywhere within a plenum have a flame spread index of 25 and a smoke developed index of 50 when tested to ASTM E84 or UL 723. Starting in 2012 and continuing through current versions, the ICC model building codes tightened the requirement by adding that the flame and smoke ratings must be listed and labeled with a Nationally Recognized Testing Laboratory (NRTL). Now that a majority of jurisdictions have adopted the 2012 codes or beyond, it is critical to only specify and install insulation materials on a duct or in a plenum that meet the listing requirement.

Third-Party Certification

Within the ICC model codes, requirements for mechanical insulation products are contained in the International Mechanical Code (IMC) and Internal Energy Conservation Code (IECC). Current versions of these codes require not only achievement of specific flame and smoke ratings according to ASTM E84 or UL 723 but also third-party certification of the ratings by an Occupational Safety and Health Administration (OSHA)- approved NRTL that also administers follow-up audits and testing when materials are installed within an air duct or plenum.

Prior to the 2012 versions, the IMC and IECC model codes did not require third-party certification to ASTM E84 or UL 723 for air duct or plenum installations. Therefore, manufacturers of elastomeric insulation have not historically undergone third-party certification. These products were instead tested by accredited labs but not certified by an outside agency with follow up testing and audits.

Listed and Labeled

The current language in the IMC 602.2.1 Materials within plenums, says “…materials within plenums shall be noncombustible or shall be listed and labeled as having a flame spread index of not more than 25 and a smoke-developed index of not more than 50 when tested in accordance with ASTM E 84 or UL 723.”

According to IMC, a “listed” product included in an NRTL’s published product directory indicates that it meets the appropriate designated standards or has been tested and found suitable for a specific purpose. To maintain listed and labeled status, follow-up testing and audits are required to ensure continued compliance with the standards or specified use. When a product is “labeled”, it has the label, symbol, or other identifying mark of the NRTL that has certified the product’s compliance with the appropriate standards or performance.

The Best Choice – ArmaFlex Ultra

At Armacell, we have an ongoing commitment to safety goals and objectives, going above and beyond existing standards and compliance. As such, we opted to go the extra step and develop new elastomeric products that would stand up to the rigorous testing, auditing, and safety standards of UL, the largest and most recognized third-party safety and certification organization in the world.

We submitted our newest insulation product line, ArmaFlex® Ultra with FlameDefense™ Technology, to UL for UL 723 evaluation where they were tested and proven to have 100% consistent and code compliant results, earning them the UL Classified mark with a rating of 25/50. This makes ArmaFlex Ultra the first elastomeric insulation in the industry to be Classified by UL to UL723 at 25/50. Furthermore with UL’s follow-up audits, you can be assured that the product is compliant to the current model building code requirements for insulation on a duct or in a plenum today and in the future.

To read the entire white paper, please download it here.