We have one Earth as our home and every Earth Day it is important for individuals and companies to invest in ways to protect the planet. Armacell's sustainability approach extends further than our manufacturing processes that make energy efficient insulation materials and high-performance foams. At Armacell, we strive to create sustainable value for our customers through our product solutions. We also strive to impact the environment by reducing our carbon footprint. Armacell recycles not only regular waste streams like bottles and cans, but we also recycle our production scrap material. Several of our production facilities, like our Yukon, OK plant, “reclaim” their PE product scrap for reuse on production lines which keeps the material from going into the landfill. This, in turn, means that we have more raw materials available to process which helps reduce our consumption while saving on transportation needs, energy use, and supply chain costs. Other facilities, like our Mebane, NC plant, donate elastomeric production scrap to local recycling companies to make other products like carpet underlay and padding materials.

We have one Earth as our home and every Earth Day it is important for individuals and companies to invest in ways to protect the planet. Armacell's sustainability approach extends further than our manufacturing processes that make energy efficient insulation materials and high-performance foams. At Armacell, we strive to create sustainable value for our customers through our product solutions. We also strive to impact the environment by reducing our carbon footprint. Armacell recycles not only regular waste streams like bottles and cans, but we also recycle our production scrap material. Several of our production facilities, like our Yukon, OK plant, “reclaim” their PE product scrap for reuse on production lines which keeps the material from going into the landfill. This, in turn, means that we have more raw materials available to process which helps reduce our consumption while saving on transportation needs, energy use, and supply chain costs. Other facilities, like our Mebane, NC plant, donate elastomeric production scrap to local recycling companies to make other products like carpet underlay and padding materials.  Armacell also plays its part in working towards a circular economy model by impacting single-use plastics waste. Our Brampton, Canada facility and Thimister-Clermont, Belgium facility both produces PET foam and utilize the plastics circular economy model which is a closed system that promotes the reuse of plastic products, generates value from waste, and avoids sending recoverable plastics to landfills. Essentially, after plastic bottle collection, the PET bottles are sorted and then crushed into flakes which Armacell buys as a raw material. This is followed by an in-house granulation process and, finally, extrusion foaming. Our PET foams are made without ozone-depleting HFC or CFC blowing agents and our foaming process reduces carbon dioxide emissions by 33% compared to standard PET foaming using virgin resin. In this way, used plastic bottles are converted into long-lifetime, high-value foam core materials for composite sandwich structures like wind turbine blades, high-speed train body structures, surfboards, and roofing products. Since PET production started in 2010, we have used more than 1,700,000,000 recycled PET bottles in our worldwide PET foam production.

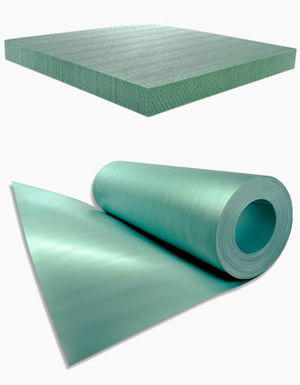

Armacell also plays its part in working towards a circular economy model by impacting single-use plastics waste. Our Brampton, Canada facility and Thimister-Clermont, Belgium facility both produces PET foam and utilize the plastics circular economy model which is a closed system that promotes the reuse of plastic products, generates value from waste, and avoids sending recoverable plastics to landfills. Essentially, after plastic bottle collection, the PET bottles are sorted and then crushed into flakes which Armacell buys as a raw material. This is followed by an in-house granulation process and, finally, extrusion foaming. Our PET foams are made without ozone-depleting HFC or CFC blowing agents and our foaming process reduces carbon dioxide emissions by 33% compared to standard PET foaming using virgin resin. In this way, used plastic bottles are converted into long-lifetime, high-value foam core materials for composite sandwich structures like wind turbine blades, high-speed train body structures, surfboards, and roofing products. Since PET production started in 2010, we have used more than 1,700,000,000 recycled PET bottles in our worldwide PET foam production.

To read more about how Armacell invests in sustainability and how we measure up check out our recent Sustainability report here.

April 20, 2022