Members-only retail clubs have seen an increase in foot traffic due to the pandemic, especially in their frozen and refrigerated foods sections. This was no exception for a global price club retailer with over 750 locations, 39 of which are in Mexico. The organization recognized early on that this increase of customer’s purchases needed attention at three of their locations in Mexico. The decision was made to expand current refrigeration systems and install upgraded equipment at these three key locations while remaining open for business, which posed quite a challenge. The technical group of this price club chain previously obtained excellent results in similar situations by using ArmaFlex products for the main refrigeration copper lines in U.S. locations, so they wanted repeated results at these locations.

Members-only retail clubs have seen an increase in foot traffic due to the pandemic, especially in their frozen and refrigerated foods sections. This was no exception for a global price club retailer with over 750 locations, 39 of which are in Mexico. The organization recognized early on that this increase of customer’s purchases needed attention at three of their locations in Mexico. The decision was made to expand current refrigeration systems and install upgraded equipment at these three key locations while remaining open for business, which posed quite a challenge. The technical group of this price club chain previously obtained excellent results in similar situations by using ArmaFlex products for the main refrigeration copper lines in U.S. locations, so they wanted repeated results at these locations.  Hillphoenix, a leading manufacturer of commercial refrigeration display cases and systems, installed the new refrigerator and freezer sections. Their trained installers were responsible for integrating the new systems with the existing equipment, which included several types of equipment brands, lines, and the most reliable insulation materials. The key objective was to not disturb business operations or customers during the upgrade and install, while maintaining a clean project workspace. The Hillphoenix crews were very comfortable installing ArmaFlex insulation on this project’s chilled refrigerated lines, compressors, compressor racks, panels, valves, and pipes. Avoiding any dust accumulation during the ArmaFlex installation eased the contractors concerns as customers were able to shop in a clean environment without disruption. Another key characteristic that was required in the mechanical system product choices was flexibility, particularity that the insulation tube could be easily slipped over the refrigeration lines. Rigid insulation foams would not meet the project timeline due to longer installation periods, and they also had the risk of dust generation. The chain has decided to include ArmaFlex products as part of the regular specs for their new and upgraded refrigeration lines in the future due to the great success.

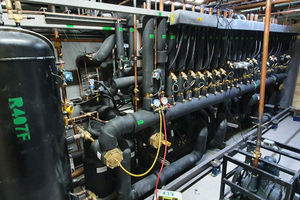

Hillphoenix, a leading manufacturer of commercial refrigeration display cases and systems, installed the new refrigerator and freezer sections. Their trained installers were responsible for integrating the new systems with the existing equipment, which included several types of equipment brands, lines, and the most reliable insulation materials. The key objective was to not disturb business operations or customers during the upgrade and install, while maintaining a clean project workspace. The Hillphoenix crews were very comfortable installing ArmaFlex insulation on this project’s chilled refrigerated lines, compressors, compressor racks, panels, valves, and pipes. Avoiding any dust accumulation during the ArmaFlex installation eased the contractors concerns as customers were able to shop in a clean environment without disruption. Another key characteristic that was required in the mechanical system product choices was flexibility, particularity that the insulation tube could be easily slipped over the refrigeration lines. Rigid insulation foams would not meet the project timeline due to longer installation periods, and they also had the risk of dust generation. The chain has decided to include ArmaFlex products as part of the regular specs for their new and upgraded refrigeration lines in the future due to the great success.

Specifying for Value

Energy efficiency is vitally important as chilled systems need to function at top performance, which means they require the proper insulation. Armacell’s insulation systems are ideal for insulating miles of liquid and suction lines, chilled water piping, chillers and cooling tanks. Insulating pipes, refrigeration lines or cooling equipment not only promotes energy efficiency, but it also prevents condensation on below-ambient temperature surfaces—a critical issue for this industry. Specifying Armacell’s Supermarket Solutions is prudent for supermarkets, grocery stores and cold food distribution points as we offer two insulation package levels each tailored to code compliance, system performance and budget, making specifying easier. Our products are always fiber-free, formaldehyde-free and low VOC making them an excellent option for any environment. Its closed-cell structure also prevents moisture ingress and naturally resists the growth of mold and mildew. ArmaFlex tubular pipe insulation comes in many sizes and thicknesses from 3/8” to 2” to accommodate diverse climate temperatures and humidity levels, making it an excellent choice for sustainable systems around the world.

Energy efficiency is vitally important as chilled systems need to function at top performance, which means they require the proper insulation. Armacell’s insulation systems are ideal for insulating miles of liquid and suction lines, chilled water piping, chillers and cooling tanks. Insulating pipes, refrigeration lines or cooling equipment not only promotes energy efficiency, but it also prevents condensation on below-ambient temperature surfaces—a critical issue for this industry. Specifying Armacell’s Supermarket Solutions is prudent for supermarkets, grocery stores and cold food distribution points as we offer two insulation package levels each tailored to code compliance, system performance and budget, making specifying easier. Our products are always fiber-free, formaldehyde-free and low VOC making them an excellent option for any environment. Its closed-cell structure also prevents moisture ingress and naturally resists the growth of mold and mildew. ArmaFlex tubular pipe insulation comes in many sizes and thicknesses from 3/8” to 2” to accommodate diverse climate temperatures and humidity levels, making it an excellent choice for sustainable systems around the world.

Download Price Club Retailer Case Study here.