By 2100, the world’s population is estimated to grow to 11 billion people and there will be major strains on natural resources including energy, minerals, food and water. Supporting a global food supply chain will require heavy refrigeration systems and application use. These low temperature systems such as refrigeration or cold chain transportation need proper insulating to remain energy efficient and control condensation. Temperatures for refrigeration and cold chain transportation can range from -100°F to 31°F and these systems are usually found in supermarkets, food processing, and transportation environments. When operating at such low temperatures, moisture in the air will condense or freeze on or within the insulation or cold pipe surface. Unless the system is protected by sufficient thickness and adequate vapor retarders, insulation can become wet, causing corrosion, which in turn causes it to become ineffective.

By 2100, the world’s population is estimated to grow to 11 billion people and there will be major strains on natural resources including energy, minerals, food and water. Supporting a global food supply chain will require heavy refrigeration systems and application use. These low temperature systems such as refrigeration or cold chain transportation need proper insulating to remain energy efficient and control condensation. Temperatures for refrigeration and cold chain transportation can range from -100°F to 31°F and these systems are usually found in supermarkets, food processing, and transportation environments. When operating at such low temperatures, moisture in the air will condense or freeze on or within the insulation or cold pipe surface. Unless the system is protected by sufficient thickness and adequate vapor retarders, insulation can become wet, causing corrosion, which in turn causes it to become ineffective.

Reasons to Insulate a Refrigeration System

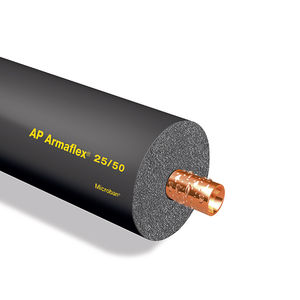

Food transportation is a real future challenge on a global scale due to the food miles certain foods have to travel. Food miles are the distance food moves from its origin to its destination and they are calculated by CO2 emitted per mile per ton of food. To help reduce the energy use of a refrigeration system supporting the transportation of food, it is critical to insulate chilled pipes or air handling units to control temperatures and the process. Selecting closed-cell elastomeric foam insulation, like ArmaFlex®, is the most effective means of providing condensation and moisture control within an insulation system on refrigerant piping, drains and ducts. If moisture intrudes the insulating material surrounding refrigeration piping, thermal efficiency is lost. Sufficient insulation thickness is also needed to keep the surface temperature above the highest possible design dewpoint temperature of the ambient air so condensation does not form on the surface. Did you know that for every 1% in moisture gain, there is a 7.5% loss in thermal efficiency? Even a single percent increase in moisture will equate to a 7.5% increase in thermal conductivity (Thermal k)! When insulation loses its ability to insulate, energy is lost and the equipment must work harder to maintain the desired chilling level. In a refrigeration system, this condition leads to energy loss and higher operating costs.

How Armacell is Helping Support This Megatrend Around the World

Armacell manufactures innovative, technical insulation solutions and components that conserve energy, reduce fuel consumption and decrease CO2 emission to improve cooling systems. With a water vapor permeability of 0.050, ArmaFlex insulation is nearly water-proof and does not require an additional vapor retarder. Not only does closed-cell foam insulation possess a low permeability rating, but it is also much less vulnerable to punctures and tears that can impair the thermal effectiveness of open cell and fibrous materials. Future refrigeration systems supporting large scale, global food supply chains will require efficient products to conserve energy and keep food miles to a minimum to help feed the world.