Installation tips and instructions for installing Armacell foam insulation products.

Installation tips and instructions for installing Armacell foam insulation products.

By Mark Hayes - Armacell Insulation Application Manager

Working with Armaflex

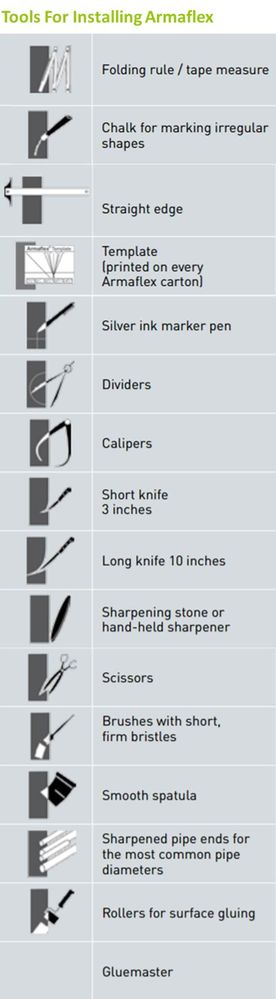

• Use good quality tools: a sharp, non-serrated knife, fresh Armaflex adhesive, denatured alcohol and a short, firm bristle brush.

• Oval tubes should always be split on the flat side.

• Use clean Armaflex material – with no dust, dirt, oil or water on the surface. If present, clean with denatured alcohol.

• Use correctly dimensioned material! Never pull glued joints when sealing them; always push them together.

• Turn systems off if running. Never insulate plant and systems in operation! Wait 36 hours for the adhesive to cure before restarting insulated plant.

• Armaflex tape should not be used as the only connection for butt and longitudinal joints and seams. If required, apply only to joints and seams that have been glued with Armaflex adhesive and only after 36 hours to allow complete offgassing of the adhesive solvent.

• WB Finish paint can be applied immediately after the insulation has been installed, with a second coat applied no sooner than 4 hours, to provide UV protection (see Outdoor use of Armaflex in our Application Manual page 14). Two coats is the minimum requirement.

• Insulating around bends – Do not slide Armaflex insulation around pipe bends when the insulation thickness is 1/2” or greater. A fabricated mitered fitting cover must be used.

• When heat trace cables are used on piping, it is recommended to increase the Armaflex tube up to the next ID size for a proper fit.

For more proper install techniques visit our page with North America Installation Application Guides here.