Cumberland Valley High School Mechanicsburg, PA

Fiber-Free Insulation and IAQ are High Priorities for Pennsylvania High School

Project: Cumberland Valley High School, Renovation and New Construction

Project: Cumberland Valley High School, Renovation and New Construction

Location: Mechanicsburg, Pennsylvania

Objectives: Install high efficiency, fiber free, mold-retardant insulation for long-term reliability and easy maintenance

Architect: The Ray Group

Contractor: EIC Insulation

PROBLEM: Create a Fiber-free Indoor Environment While Preventing Mold & Mildew

SOLUTION: Armaflex Closed-cell Elastomeric Insulation for Pipes & Air Ducts

Longevity of products and equipment is always a concern for schools undergoing renovation. In the case of Cumberland Valley High School in Mechanicsburg, PA, that concern was heightened, largely because of what the school district had endured over the past decade as a result of asbestos removal.

These days, the Cumberland Valley School District is determined that any new construction or major renovation will last a minimum of 30—even 50 years. But that’s not possible when EPA regulations deem certain construction materials (i.e., asbestos) unsafe.

For this reason, long before the massive renovation of Cumberland Valley’s largest school began in 2000, the school board was intent on making it a “fiber-free zone”.

“We’ve spent upwards of two million dollars in asbestos removal,” said Lee Brandt, a construction representative for Cumberland Valley School District.

Regardless of the conflicting reports on the health effects of fibers in the air stream, Cumberland Valley simply didn’t want to take any chances.

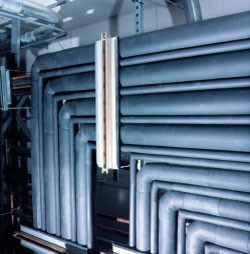

Part of that decision to go “fiber-free” included the selection of AP Armaflex® closed-cell elastomeric foam insulation for piping and ductwork throughout the school. The square footage of duct liner installed in the school, which is attended by over 1900 students, made it one of the largest foam insulation projects in the history of Pennsylvania schools at that time. The installation also included about 10 miles of pipe insulation. The choice of closed cell Armaflex materials was a clear indication that Cumberland Valley was committed to their decision to limit fiber in the schools.

Craig Diamond of EIC Insulation, the subcontractor on the Cumberland Valley project, has been installing closed-cell insulation since Armaflex was first manufactured. According to Diamond, this project was a clear exception to a common rule in the construction industry, one which is changing, at least regarding insulation.

“Most people go for cost, and in this case cost was secondary or even lower in priority,” said Diamond. Keeping the school fiber-free was number one. Besides, the cost of insulation material is a fraction of the typical total construction costs, and can often prevent far more serious and expensive future problems.

Closed-Cell Structure Prevents Condensation, Inhibits Mold

While some budgets dictate the use of alternative insulating materials, Diamond says he absolutely prefers closed-cell foam.

“It’s nicer looking, more professional, and easier to clean,” he says. “And Armaflex is probably the best anti-sweat material for cooling systems. It stops the condensation.” Since condensation can lead to mold, this is a big deal for any school system—or any occupied facility for that matter. Armaflex closed-cell insulation won’t absorb moisture when properly installed, and therefore inhibits the growth of mold. Other materials can absorb moisture if their separate vapor retarders are damaged.

Mold was big concern for the school, says Tom King of The Ray Group, the architect of record for the Cumberland Valley project. “We have lived through litigation over it,” remarked King, “And with the fresh air requirements from ASHRAE for public schools, it puts a premium on dehumidification, so we have to take a lot of steps to avoid moisture.”

One of these steps includes designing a system for cleanliness. A lot depends on how well the system is maintained, how often the filters are changed, how clean the coils are, and other factors, said King. Unlined open cell insulation inside a duct provides a good place for dust to settle. Closed cell insulation, however, is not only easy to clean, its smooth surface actually inhibits the accumulation of dirt and contamination.

AP Armaflex Duct Liner is a patented, self-adhering product specifically engineered to insulate air ducts while providing added protection against mold, mildew and airborne fibers. It is also NFPA 90A and 90B approved and has low water vapor transmission properties. In addition to duct liner, AP Armaflex is the preferred pipe insulation for preventing condensation and moisture intrusion on chilled water systems and is also available in sheet and roll form for insulation larger tanks, vessels and pipes. It is the original elastomeric foam insulation and a recognized and preferred solution for cold systems and air handling systems worldwide.

Download the Case Study PDF here.