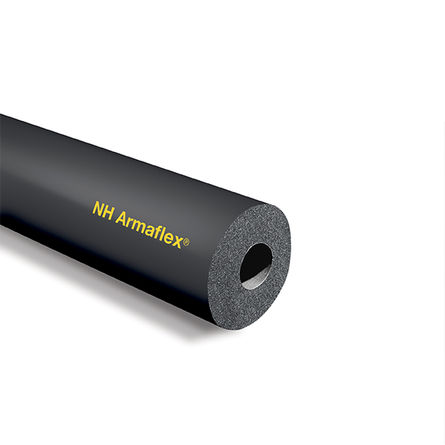

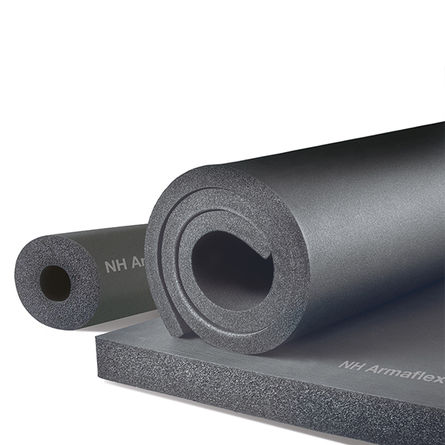

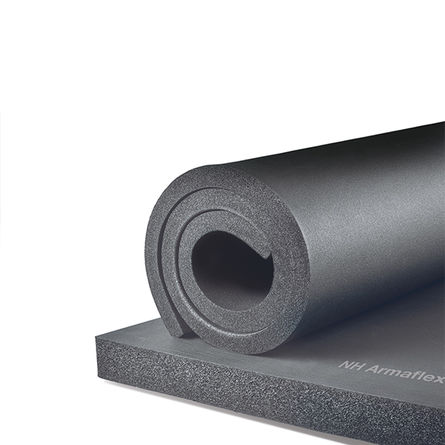

NH ArmaFlex

Non-halogen Insulation in Tubes, Sheets and Rolls

NH ArmaFlex was specially developed by Armacell to minimize the density of smoke in a fire event and eliminate corrosive acid gases from combustion. NH ArmaFlex will not carry a progressive flame, and is formulated without chlorine, bromines, or PVC.

NH ArmaFlex is a non-halogen elastomeric insulation developed for sweat control in environments that require specific protection against smoke containing acid gases.

Overview

The first non-halogen flexible insulation introduced for use on ships.

Product Advantages

Non-halogen formula

Contains no chlorine, bromines, or PVC

No corrosive acid gases from combustion

Indoor Air Quality: Low VOC, fiber-free, non-particulating, formaldehyde-free insulation

GREENGUARD Gold Certified

Closed-cell foam structure prevents moisture wicking and eliminates need for additional vapor retarder

Application Areas

NH ArmaFlex is used as insulation and protection for piping, tanks and air ducts, and to prevent stress corrosion with stainless steel pipes in the following applications:

Anywhere non-halogen or chlorine-free materials are required

Exterior applications must be protected against radiation

Specifications

NH ArmaFlex is a nonhalogen flexible elastomeric thermal insulation, gray in color, supplied as unslit tubing, sheets and rolls

Sizes:

See Submittal sheet for complete size options.

Specifications Compliance:

UL-V-O and HF-1 File Number E55798

ASTM C534 Type 1 (Tubular) Grade 3, Type II (Sheet) Grade 3

* Contact Armacell for details

Approvals, Certifications, Compliances:

GREENGUARD Gold Certified

Manufactured without CFCs, HFCs, HCFCs, PBDEs, or Formaldehyde.

All Armacell facilities in North America are ISO 9001 certified.

R-Values:

Link to the NH ArmaFlex Tolerances and R-values table here.

For complete Specification details, download the product submittal sheet.

Accessories

ArmaFlex 520 and 520 Black Adhesive – Air-drying, solvent-based contact adhesive for strong bonds and tight seams.

ArmaFlex Low VOC Spray Contact Adhesive – Low VOC adhesive in 27 pound aerosolized canisters

ArmaFlex WB Finish – Latex-based, UV resistant protective coating for indoor or outdoor applications

NH ArmaFlex Insulation Tape – black foam, pressure-sensitive seam tape

![[[relatedProduct.name]]]([[(relatedProduct.images.length && relatedProduct.images[0] || '')]])