SUPPLY CHAIN REACTION - Mueller and Armacell

MUELLER DIE CUT SOLUTIONS CAPABILITIES

- Mueller has the equipment, talent, and manpower to take your project from concept through production:

- Die Cutting: Flat bed and rotary

- Value-Added Center: Hot wire cutting, ultrasonic welding, and more

- Laminating: Wide and narrow webs, muti-layer capable, and more

- CNC Cutting: Water jet, router, and digital knife

- Precision Slitting: Lathe slitting and rewind slitting

INTRODUCTION

As with many industries, automotive gaskets must meet stringent requirements for performance, quality, and safety. And, to avoid delayed manufacturing timelines, suppliers of these materials are expected to adhere to tight deadlines throughout the supply chain. Armacell repeatedly demonstrates their ability to meet customer expectations for timeliness and material specifications, including a wide range of products that meet the strict automotive specifications. And, for decades, Mueller Die Cut Solutions has helped their customers with their custom fabrication of flexible materials, going beyond manufacturing to the “Mueller Way” of exceptional quality, ingenious engineering, and pinpoint customer focus. Together, the Armacell / Mueller partnership addressed the challenges for timely HVAC gasket supply experienced by a major automotive supplier.

As with many industries, automotive gaskets must meet stringent requirements for performance, quality, and safety. And, to avoid delayed manufacturing timelines, suppliers of these materials are expected to adhere to tight deadlines throughout the supply chain. Armacell repeatedly demonstrates their ability to meet customer expectations for timeliness and material specifications, including a wide range of products that meet the strict automotive specifications. And, for decades, Mueller Die Cut Solutions has helped their customers with their custom fabrication of flexible materials, going beyond manufacturing to the “Mueller Way” of exceptional quality, ingenious engineering, and pinpoint customer focus. Together, the Armacell / Mueller partnership addressed the challenges for timely HVAC gasket supply experienced by a major automotive supplier.

THE SITUATION

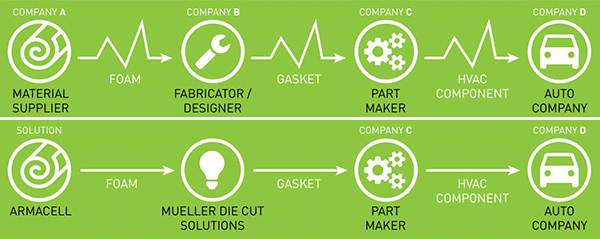

Mueller takes pride in their ability to problem solve for their customers. In this situation, Mueller was approached by an existing customer (Company C. See Figure 1 Supply Chain Situation), a large supplier of thermal management parts and programs for the automotive industry, regarding challenges they were experiencing with the timely supply of an HVAC component to their customer (Company D), an automotive manufacturer. The part of interest was a plastic injection-molded HVAC component that requires a conformable gasket to seal between the multiple plastic parts that have mating surfaces with varying tolerances. Company C’s ability to provide this HVAC component in a timely manner was challenged by Company D’s unpredictable ordering and tight turnaround times as well as the supply chain. Company C relied on a fabricator (Company B) to supply the gasket, while Company B sourced the gasket material from a materials supplier (Company A). To address the timing issues related to the supply chain, Company C opted to find an alternative fabricator to replace Company B. Company C turned to Mueller for assistance, based on their long-standing relationship and Mueller’s ability to successfully manage similar supply challenges in the past.

Supply Chain Situation (Figure 1)

THE SOLUTION

Mueller had not previously worked with Company A and preferred to utilize an already established supply partnership. Once Company C approved the request to supply material from another gasket material supplier, the Mueller team turned to Armacell. Not only had they successfully partnered before but they also knew that Armacell had thematerial capabilities and could accommodate quick turn-around times.

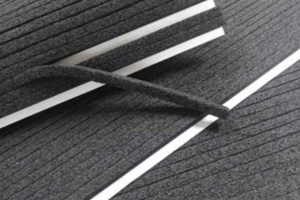

Mueller approached Armacell with specific material requirements, for which the Armacell team suggested the use of Armacell’s EnsoLite® EF0 foam. It is a conformable crushed foam that will fill the gaps in the uneven parts, it’s EPDM based and meets the auto maker’s specified temperature range and it’s compatible with Mueller’s adhesive systems. To reduce the scrap rate and maximize the yield from this material, which was provided by Armacell in 54" wide rolls, the Mueller team developed a three step process: 54" wide EnsoLite EF0 is laminated with a pressure-sensitive adhesive paper The foam is kiss-cut leaving the paper backing intact Then the material is cut to multiple lengths. Prototypes from this process were provided within a week of Company C’s request for Mueller’s assistance. Based on these prototypes, Company C approved the final deliverable as well as the EnsoLite material. The final hurdle was accounting for Company D’s unpredictable ordering and short turnaround times. For this, Mueller developed a safety stock program that was developed from analysis of pertinent information provided by Company C. The subsequent projections allowed Mueller to prepare and stock inventory for shipment – after step 3, the material was rolled up again, placed in boxes, and labeled ready for shipment. When an order is received from Company C, the material is shipped next day.

THE OUTCOMES

Within three weeks from the date of request, the gasket material from the Armacell/Mueller partnership was in the HVAC components provided to Company D. This was achieved by a combination of factors, including Armacell’s ability to quickly supply the Material. Compared with the die-cut process used by Company B, which produces a considerable amount of scrap material, Mueller achieved a greater yield with their three-step process. Perhaps most importantly for Company C, partnering with Mueller has ensured no disruption in supply and delivery for the year since implementation. “We’ve had 100% accuracy so far,” says Michael Bryant, Mueller Sales Manager. “No rejects, and no late shipments, even with the continuous ebbs and flows of the customer’s requests”.

EnsoLite® EFO Foam Specifications

// Black, very soft, semi-closed cell “crushed” EPDM, 4-8 lb/ft3 density product

// Typical 25% compression deflection values of 1.0 psi max.

// Meets the horizontal burn / flame requirements of FMVSS-302 at 1/8" and higher

// UL Listed to UL94 V-0, 5VA, and HF-1 at specific thicknesses

// Wide temperature range

// Excellent UV, ozone, and weathering

For more information about Mueller Die Cut Solutions, visit: www.muellercustomcut.com

Download Mueller Automotive Gaskets case study here.