Never underestimate the impact of the relative humidity when selecting an insulation thickness

Condensation is never a good thing when it comes to cold water or refrigeration piping. It can cause any number of costly problems, from deteriorating the thermal effectiveness of insulation to dripping on building components, occupants or even manufactured products. But what is condensation and why does it occur?

To understand the mystery behind condensation it’s important to recognize the relationship between water, air and temperature.

The air in our indoor and outdoor environments always contains some amount of water. You can’t see the water because it is held in a gaseous state.

Warm air can hold more liquid in a gaseous state than cold air. That’s why you can literally “feel” the moisture in the air on a hot, humid day. How much liquid the air can hold depends on the ambient temperature and relative humidity. Relative humidity is the amount of moisture in the air compared to the amount of moisture the air is capable of holding at a given ambient temperature. When the air can’t hold any more moisture, the water vapor in the air condenses and you have rain, dew or condensation.

The point at which water vapor changes from gas to liquid is called the dew point. More specifically, dew point is the temperature at which moisture saturates the air. So for every degree of ambient temperature and relative humidity, there is a specific dew point – a point where the air simply cannot hold another drop of liquid vapor. Because cold air can’t hold as much moisture as warm air, cooling the air decreases the amount of moisture in the air, resulting in liquid moisture that makes things wet.

This is why it is essential to insulate cold piping. Without insulation, cold water piping would “sweat” just like a glass of ice water on a hot day. The air around the cold pipe or glass is cooled below the dew point, and thus condensation begins to form.

How Much Insulation Does It Take to Prevent Condensation?

We can prevent condensation from occurring by insulating the pipe with enough insulation to keep the air around the pipe from dropping below the dew point. But how much insulation is enough?

Obviously, there is no one-size-fits-all when it comes to insulation for cold pipe. It depends on the dew point of the air, which fluctuates according to the ambient temperature and the relative humidity. These values not only vary from space to space, but from moment to moment.

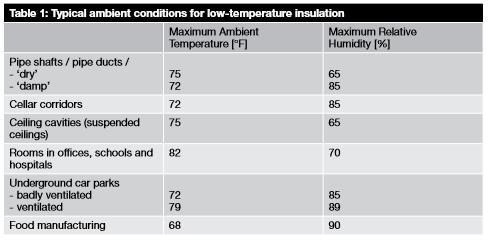

To ensure that there is sufficient insulation we must know the maximum ambient temperature expected to occur within the space as well as the maximum relative humidity. In conditioned spaces the HVAC system may be designed to provide 75°F and 50% RH in the summer but this does not represent the worst case. Part-load conditions or shut downs of the equipment when the building is unoccupied can create much more severe conditions. In addition, even though a space where cold service pipe is located might be conditioned, such as above a suspended ceiling, the temperature and relative humidity is often higher in these locations. This is why it is important to determine the most severe ambient conditions for each specific location and size the insulation to prevent condensation for these conditions. The table below reflects typical maximum conditions in several common spaces.

In unconditioned spaces it is not be possible to prevent condensation in all situations because the relative humidity will reach or approach 100% at times. In these cases it is common to use 90% as the maximum relative humidity but dry climate may use lower values.

Knowing the operating and ambient conditions is the first step to selecting the proper thickness of insulation. The second step is relating these requirements to the thermal characteristics of a given insulation material, a task that can be quickly and easily accomplished using calculation programs like ArmaWin.

It is especially important to never underestimate the impact of the relative humidity on the insulation thickness needed to prevent condensation. Surprisingly, a mere 10 percent increase in humidity can sometimes mean that the insulation needs to be twice as thick.

Have more questions about specifying the right thickness of insulation for your project to prevent condensation? Contact our technical managers for help with your specific application.