By Matthew Hawn - Armacell Market Development Manager

Part 1: Insulation is the Key to Achieving Higher Energy Efficiency

Thermal conductivity is a central technical property, but it should not be the only one taken into account when selecting an insulation material. Standard-compliant fire behavior, mechanical stability (aging behavior), and ease of installation are further obvious requirements that insulation materials must meet. But what about protection from moisture ingression? Is there a risk of corrosion under insulation (CUI)? Does the material meet not only thermal but also acoustic insulation requirements, such as sound reduction and/or absorption?

Armacell has investigated these and other properties of insulation materials in comprehensive tests. The key results will be presented in a series of articles. But first we will look at the increasing significance of technical insulation in view of climate change and other global trends.

Development of insulation technology

The topic of thermal insulation is as old as humankind: Stone-Age man made clothing out of animal fur to protect himself against the cold in northerly regions. Humans have been using the principle of the low thermal conductivity of static air layers for thousands of years. The reed- or straw-thatched houses constructed in the Bronze Age provided good thermal insulation. Double-shell walls were also built at this time: by filling the space between two wattle and daub walls with dry grass, excellent insulation values were achieved.

A crucial factor in the further development of insulation materials was the advancement in refrigeration techniques which led to the construction of the first cold stores at the beginning of the 20th century. Initially these were insulated with modified corkboard. Further impulses for the development and use of insulation materials came from the energy-saving regulations which were passed in many countries in reaction to the oil crises in the 1970s. Nowadays, many different insulation materials are available for a wide range of applications.

It was the oil crises that made the public aware of the economy’s great dependence on oil and put this issue on the political agenda. Concerns over the finite nature of fossil fuels and its impact on the environment lead to new social movements such as the search for alternative technologies and organizations calling for the reduction of human impact on the environment. While early scientific studies on climate change were initially dismissed, today there is widespread agreement in the scientific community that climate change is impacted by human action and has dangerous consequences for the environment. It is now understood that we are living in an era of climate change.

Building sector offers greatest energy-saving potential

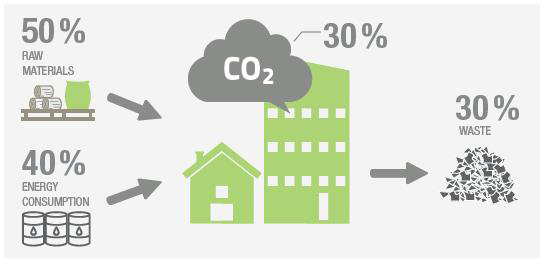

The signing of the global climate agreement in Paris by the international community of states marks the beginning of a global ‘energy revolution.’ For the first time, all 195 member states of the UN Framework Convention on Climate Change committed themselves to protecting the climate and unanimously agreed to restrict global warming to below 2 °C compared to the level before the beginning of industrialization. Since this time, the United States has officially withdrawn participation in this agreement, however many industry leaders in the private sector of the United States have taken up this challenge. Originally, the US agreed to reduce carbon emissions 26-28% by 2025 vs 2005 carbon emissions. The greatest potential for savings is to be found in the building sector: industrial nations consume large amounts of energy in transportation and industry, but the building sector accounts for the majority – around 40% of total energy consumption! At the same time, the construction industry is one of the most resource-intensive business sectors and 30 – 40% of the world’s waste results from the demolition and disposal of buildings. The building sector is not only the largest single source of global raw material use and greatest producer of waste, but buildings have the greatest environmental impact during their operation: some 40% of greenhouse gases worldwide are produced in buildings.

Figure 1: Buildings are the largest single source of raw material use, the greatest producer of waste. They account for 40% of the world’s energy consumption and are responsible for 30% of CO2 emissions worldwide

Almost half of the energy demand for buildings is required for heating and cooling. In US households, heating and hot water alone account for 18% of total final energy use. Cooling of the space consumes another 15% of the energy use. In the US, 65% of electricity is generated from burning fossil fuels, while only 15% comes from renewable sources. In order for human impact on the environment to be minimized, energy consumption for heating and cooling buildings must be drastically reduced and the use of fossil fuels minimized.

The problem is exacerbated not only by the relatively long lifespan of buildings and the outdated building service equipment found in existing buildings, but also by a global construction boom. The United Nations Environment Program (UNEP) estimates that greenhouse gas emissions from the construction sector will double over the next 20 years unless countermeasures are taken. No insulation or inadequate insulation, old boilers and over-sized, inefficient circulation pumps cause gas, oil and electricity consumption in buildings to soar. Existing buildings need to be better insulated and inefficient heating must be replaced by modern systems. While in individual cases the energy requirement in existing buildings can be reduced by up to 90%, on average a reduction of around 50% is achieved.

Increased energy efficiency is crucial

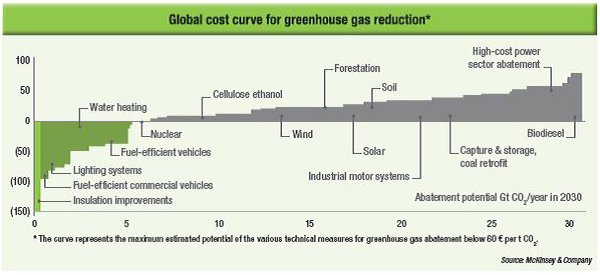

Up to 80% of the energy required in buildings could be saved just by using existing, tried-and-tested technologies. From an economic point of view, programs to increase energy efficiency are the most practical way to reduce greenhouse gases. Experts expect that in the short term at least twice as much can be achieved through energy-saving measures as through the greater use of renewable energies. This is confirmed by a study on the size and cost of measures to reduce greenhouse gas emissions conducted by McKinsey & Company. The extensive study investigated more than 200 technologies from 10 different areas and all relevant sources of emission (not only energy-related ones) in 21 different regions around the globe (see Figure 2).

Figure 2

Figure 2

At the low end of the curve are measures for improving energy efficiency. These measures reduce greenhouse gas emissions by decreasing the demand for energy. At the top end of the cost curve are technologies that abate greenhouse gas emissions (such as wind power and carbon capture and storage). The curve also shows ways to reduce emissions by replanting tropical forests and switching to agricultural practices with greater greenhouse gas efficiency. On the left are the most profitable measures for abating emissions, i.e. measures with the greatest savings potential and the lowest investment costs. The cost curve for greenhouse gas abatement provides a quantitative basis for judging which measures are the most cost-effective for reducing emissions.

Insulation is the key technology

Of the many technologies investigated in the study, insulation is the most effective and least expensive method to reduce CO2 emissions. This is due to the enormous savings potential. Insulation decreases the thermal losses of the biggest ‘energy guzzlers,’ thus leading to a reduction in the amount of energy required for heating and cooling buildings. Insulation is the key technology for increasing energy efficiency. Wherever energy is produced, transported or stored, part of the valuable resource is lost if equipment is poorly insulated. This is equally true for building service equipment and industrial plants. Mechanical insulation is one of the simplest, most cost-effective measures for energy-efficient building renovations and payback can be realized very quickly. No other investment in climate protection has comparable potential and such a short payback period. Accounting for an average of just 1% of the total cost of the mechanical equipment, insulation ensures higher performance, longer service-life, and greater efficiency of equipment in both buildings and industry.

Ecofys, a leading international consultancy in the field of renewable energies and energy efficiency, produced a study that shows insulation of industrial plants is not usually economically considered. However by installing optimized insulation systems, it is possible to achieve energy savings of up to 45%. Therefore, insulation investments will often payback after just a few months. The industry sector, unlike the building or transportation sector, does not yet have any corresponding legal regulations or energy-saving programs.

Global megatrends drive the demand for technical insulation

Nowadays business and society change much more rapidly than at the time of the industrial revolution. The development of the internet, social networks and digital devices is a powerful illustration of the incredible pace of technological change. New technologies have always changed the world, but today that happens at much greater speed. It took around 50 years for half of the US American population to own a telephone, however, Facebook had six million users after just one year and a few years later the figure stood at one billion. Digitization is one of the megatrends which will transform companies, the economy, politics and society. Megatrends are complex change processes which alter our social and economic structures over the course of decades. Apart from digitization, globalization and the demographic shift, urbanization, energy efficiency / climate change and growing wealth are among the most important megatrends which will shape overall economic development over the coming years and reinforce current trends in refrigeration and air-conditioning technology.

Megatrend ‘energy efficiency’

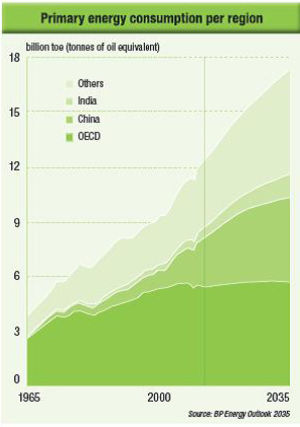

A future-compliant, sustainable energy supply is one of the greatest societal challenges of our times. Global energy consumption will continue to rise: according to British energy group BP, in 2035 one third more energy will be needed on Earth than today (see Figure 3).

Figure 3

Figure 3

An energy revolution can only be achieved if energy efficiency is increased in all areas. In industry it is first necessary to raise awareness for the fact that the optimized insulation of process equipment has an unrivalled return on investment. In the industrial nations, the requirements regarding the energy efficiency of buildings are increasing and higher insulation standards for building service equipment are defined in energy-saving laws – both for the construction of new buildings and the renovation of existing ones. Rising energy prices, threats to the security of supply as fossil fuels become scarcer and more expensive, soaring energy consumption in emerging countries, and not least the consequences of climate change, will all inevitably lead to the introduction of stricter energy-saving laws.

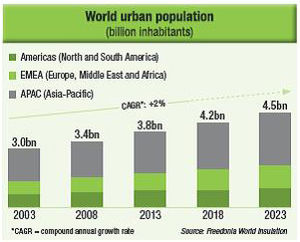

Megatrend ‘urbanization’

Today, over half of the world’s population lives in towns or cities – more than ever before. And the trend is set to continue: in future more and more people will move from rural to urban areas. This migration to the cities is particularly pronounced in the emerging countries, but the trend is also unbroken in highly developed countries with low population density. In fast growing countries such as India and China, the demand for technical insulation materials is rising due to the growing construction sector. In the industrial nations, the trend has led to a higher demand for property in towns and cities. Land is becoming scarce, a factor that is reflected in the construction of ever taller buildings. To ensure that the infrastructure can keep pace with the growing cities, a political framework has to be defined for the construction of new buildings and energy-efficient modernization of existing ones. Retrofitting insulation to accessible pipes is one of the simplest and most cost-effective energy-saving measures in existing buildings.

Figure 4

To confront advancing climate change and meet the growing energy demand it is imperative that resources are saved in buildings. Buildings equipped with modern environmental and HVAC equipment will increasingly serve as a model for a new generation of buildings. Green building stands for future-compliant buildings and the responsible use of resources.

Megatrend ‘increasing wealth’

Between 1970 and 2014, the real value of the global gross domestic product rose from 12,138 to 77,451 billion US dollars. According to estimates by the World Bank, the per capita income in low-income countries will rise twice as much by 2050 as in the OECD states. From 1999 to 2009, the disposable per capita income in Asia grew by 90 %. Thanks to the internationalization of markets, emerging countries are now also participating in world trade, wealth and economic growth. Higher private incomes have been boosting the economy for years in Asia, but they have also led to a dramatic rise in CO2 emissions per capita – and it has not yet been possible to offset this development by using energy-efficient technologies.

Cold chain market is booming

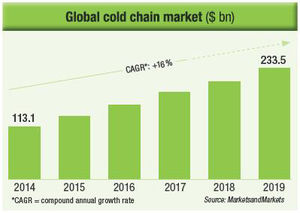

Greater wealth in emerging and developing countries is leading to changes in consumer behavior. Especially in China the demand for meat and dairy products is growing rapidly. The food supply is more varied than ever before. Thanks to modern refrigeration technology, food can now be transported around the world without any difficulty. As a result of globalization, the cold chain – continuous refrigeration during transportation from manufacturer to wholesaler to retailer to consumer – is more and more important, not only for the food industry but increasingly also for pharmaceutical and chemical products. The unbroken growth in population and rising life expectancy are additional factors which will continue to boost the global cold chain market for decades to come. Figure 5 shows the forecast development of this sector. Refrigeration and insulation technology will benefit equally from this trend. Optimal insulation of the refrigeration technology is essential to reduce the high energy costs and greenhouse gas emissions in this segment.

Figure 5

Acoustic insulation is on the increase

In industrial nations greater wealth has led to enhanced living comfort. Purely functional bathrooms have given way to home spas and, even in moderate temperature zones, air-conditioning is no longer seen as a luxury, but as an amenity which many would not like to be without. In cars it has been standard equipment for years.

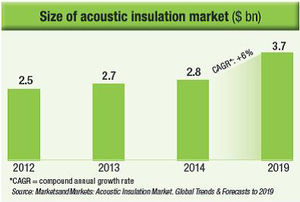

Occupants’ expectations of acoustic insulation in buildings are also on the rise: sounds that were not perceived as annoying, but simply accepted in multi-family houses twenty or thirty years ago, are today regarded as ‘unacceptable disturbance’ and lead to problems amongst the residents. The significance of acoustic insulation for people’s well-being and the quality of a building is shown by the results of representative surveys: 82% of respondents will not accept cost savings at the expense of acoustic insulation and 94% consider good sound and noise control to be important. Acoustic insulation in buildings means not only peace and relaxation, but also privacy, intimacy and a sense of security.

In the workplace, noise disturbance is not just annoying; it can also be a health hazard. The risk of cardiovascular disease, high blood pressure and migraines rises significantly. Noisy environments often lead to a drop in levels of concentration and individual performance and a rise in the number of mistakes made. In industry, the risk of accidents in the workplace increases as a result of exposure to excessive noise levels from unprotected or inadequately insulated equipment. Occupational exposure to noise causes 16% of adult disabling hearing loss worldwide. Noise-induced hearing loss has long ranked among the most common occupational illnesses in industrialized countries and comes at a huge cost to the economy.

Figure 6

In the future it will become more and more important to acoustically insulate equipment. Specifiers and plumbers must satisfy occupants’ higher expectations and continue to optimize their noise control solutions. Leading insulation manufacturers offer innovative products which minimize noise at the source and increase living comfort in buildings. For applications requiring high-performance noise absorption, such as enclosures for heat pumps and combined heat and power plants (CHPs) or casings for fans, there are new acoustic foams with excellent sound absorption properties.

Conclusion

The trends presented above often reinforce each other. For example, migration to the cities means that people will be more likely to be exposed to noise. The high rate of urbanization will further boost economic growth, but will also have consequences for the environment. Considerable resources are required for the huge building projects planned and soil sealing and the emergence of ‘heat islands’ will accelerate global warming and climate change. This is where there is a need for innovative concepts for reducing energy requirements and emissions (e.g. through energy-efficient heating, hot-water supply and air-conditioning).

According to the UN, a third of the food produced throughout the world is lost on the way from plantation to plate. Effectively insulated cold chains not only prevent the wastage of food, they also raise energy efficiency and conserve precious resources.

The key technology for increasing energy efficiency is insulation. Wherever energy is produced, transported, or stored, part of the valuable resource is lost if equipment is poorly insulated. As we will show in the next articles in this series, there are significant differences in the performance of the various materials used for technical insulation.

Article Teasers:

(1) Enormous energy-saving potential can be realized by insulating mechanical equipment. It is the most effective and least expensive way to reduce CO2 emissions.

(2) Wherever energy is produced, transported or stored, part of the valuable resource is lost if equipment is poorly insulated.

_______________________

¹https://www.eia.gov/tools/faqs/faq.php?id=96&t=3

²https://www.eia.gov/energyexplained/index.cfm?page=electricity_in_the_united_states

³https://www.euenergycentre.org/images/unep

4www.energy.gov/sites/prod/files/2016/02/f29/BTO_MYPP_2016.pdf

5www.mckinsey.com/business-functions/sustainability-and-resource-productivity/our-insights/a-cost-curve-for-greenhouse-gas-reduction

6www.staedtebauliche-laermfibel.de/pdf/Baublatt-2000.pdf

7Verbeek, Jos H.; Kateman, Erik; Morata, Thais C.; Dreschler, Wouter A.; Mischke, Christina (2012): Interventions to prevent occupational noise-induced hearing loss. The Cochrane Database of Systematic Reviews