Experts at Microban® show us how Microban technology passes the fungal test

A growing concern about our exposure to fungus and mold, along with a willingness to stop the aesthetic and surface damage it can cause, motivates many consumers to invest in products that have built-in antifungal agents. Microban®, one of the world’s leading antimicrobial and antifungal solutions specialists, is working with manufacturers who want their products to resist the damage that fungus and mold can cause.

A growing concern about our exposure to fungus and mold, along with a willingness to stop the aesthetic and surface damage it can cause, motivates many consumers to invest in products that have built-in antifungal agents. Microban®, one of the world’s leading antimicrobial and antifungal solutions specialists, is working with manufacturers who want their products to resist the damage that fungus and mold can cause.

In this blog, we’ll look at how fungus and mold impact everyday products, and how Microban professionals can ensure products pass the fungal test during the custom product development process.

Fungus and Mold – It’s Everywhere

You’ll find fungus and mold anywhere. Without antifungal coatings and additives in products, fungus and mold can contaminate our bathroom ceramics, stain our windows, and produce unsightly patches in the depths of our basements. More often than not, mold and fungus grow in areas where there is high humidity, water damage or dampness, making built-in antifungal agents key for preventing its growth.

The Impact of Fungus and Mold In Everyday Products

Everyday products without antifungal additives that are exposed to fungus and mold are affected in a variety of ways. Perhaps the most noticeable is the appearance of unsightly black stains and marks which can ruin the condition of products and surfaces. Prolonged exposure to fungus and mold can also cause the product to deteriorate at a much quicker pace, impacting its durability, longevity, and product shelf life.

How Products Can Pass the Fungal Test with Antifungal Agents

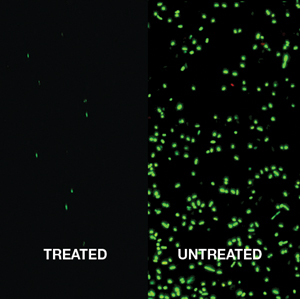

Microban works with individual manufacturers to develop customized solutions that provide products with antifungal protection. Targeted antifungal technologies are incorporated into the products during the normal manufacturing process, becoming a vital part of the product itself. When fungus and mold come into contact with the product surface, Microban’s antifungal technology penetrates the cell wall of the microbe and disrupts key cell functions so that it cannot function or reproduce.

Microban works with individual manufacturers to develop customized solutions that provide products with antifungal protection. Targeted antifungal technologies are incorporated into the products during the normal manufacturing process, becoming a vital part of the product itself. When fungus and mold come into contact with the product surface, Microban’s antifungal technology penetrates the cell wall of the microbe and disrupts key cell functions so that it cannot function or reproduce.

Offering consumers a product with custom-developed antifungal capabilities differentiates that product from unprotected competitor products. Since 2006, Armacell has manufactured foam insulation featuring Microban® antimicrobial product protection – the first foam insulation maker to do so. All of Armacell's AP Armaflex® family of products are made with Microban technology that inhibits the growth of mold and mildew in the insulation. Specifiers, building owners and contractors should choose Armacell insulation with Microban technology because of its additional protective properties that lead to a cleaner insulation for schools, hospitals and commercial buildings of all types.

To learn about Microban antimicrobial technology or to broaden your antimicrobial protection knowledge, visit www.microban.com.

Microban antimicrobial product protection is limited to the product itself and is not designed to protect the users of these products from disease causing microorganisms, food borne illnesses, or as a substitute for normal cleaning and hygiene practices. Microban International, Ltd. makes neither direct nor implied health claims for the products containing Microban® antimicrobial product protection. The information presented in this blog post is solely for the purpose of providing general information regarding Microban International, Ltd.

Source www.microban.com